Aseptic Processing: Decontamination and Sterilization Technologies

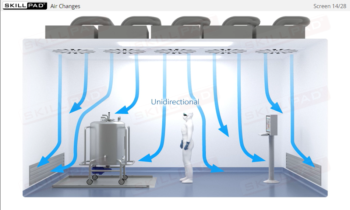

Methods typically used to decontaminate and sterilize equipment, consumables, containers/closures, and products as part of aseptic processing. Methods covered include moist heat, dry heat, hydrogen peroxide vapor, and filtration.

Part of Annex 1 training requirements.

Whether for onboarding or annual refresher training, this Module is seamlessly deployable on any LMS and can be tailored to your company’s exact needs.

Duration: 30 Mins

Grade: Premium Performance

Description

- Gain an understanding of aseptic processing including the methods used to decontaminate and sterilize equipment, consumables, and containers/closures.

- Discover how various sterilization techniques including moist heat, dry heat, hydrogen peroxide vapor, and filtration are used.

- Recognize the importance of sterilization in aseptic processing, the process of various sterilization methods, and the concept of ‘hold times’ in relation to equipment used in aseptic processing.

Learning Objectives

- Explain why injectable products must be sterile.

- Explain the purpose of cleaning, decontamination, and sterilization in aseptic processing.

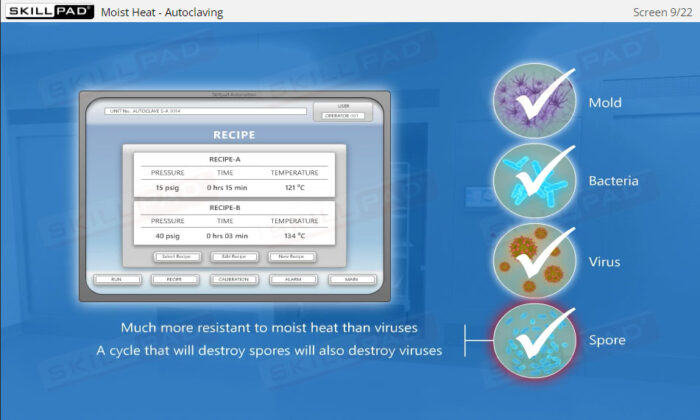

- Describe how moist heat sterilization is performed via autoclaving.

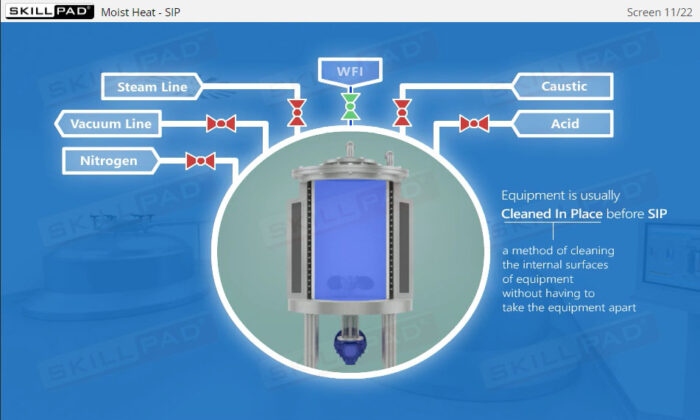

- Describe how moist heat sterilization is performed via Steam In Place.

- Describe the purpose of dry heat sterilization and how it is performed.

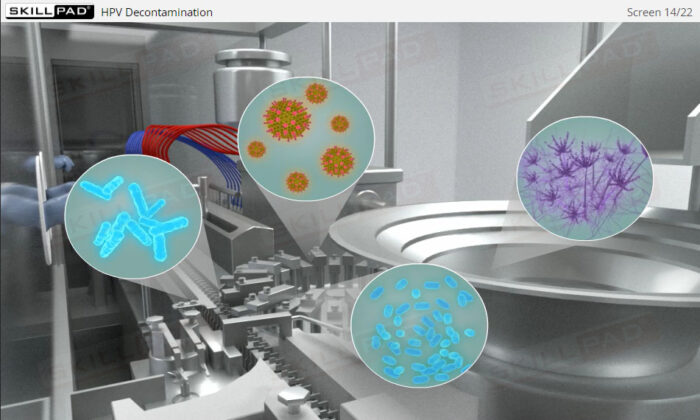

- Explain the process of HPV decontamination.

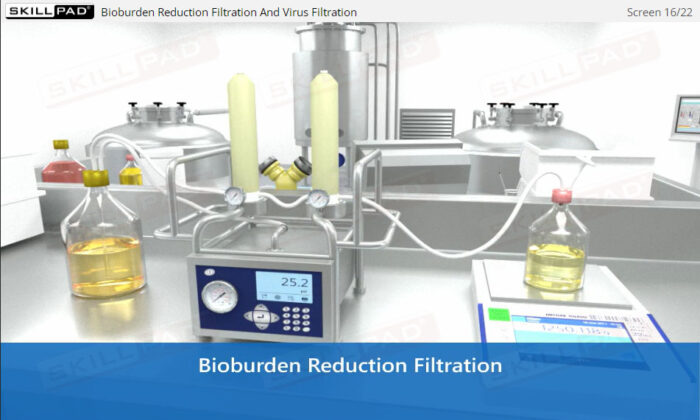

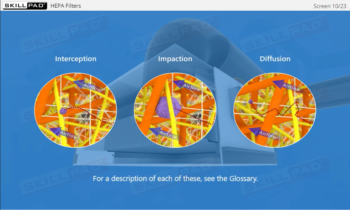

- Explain the difference between bioburden filtration and viral filtration.

- Explain what is meant by ‘hold times’ in relation to equipment used in aseptic. processing

Keywords

- Aseptic Processing

- Autoclaving

- Decontamination

- Dry Heat Sterilization

- Filtration

- Hold Times

- Hydrogen Peroxide Vapor (HPV)

- Steam In Place (SIP)

- Sterilization Technologies

Module Features

Animations

Voice Over

Knowledge Checks

Assessments

SCORM/AICC compatible

Full Screen