Aseptic Processing – Working with Isolators

Coming Soon!

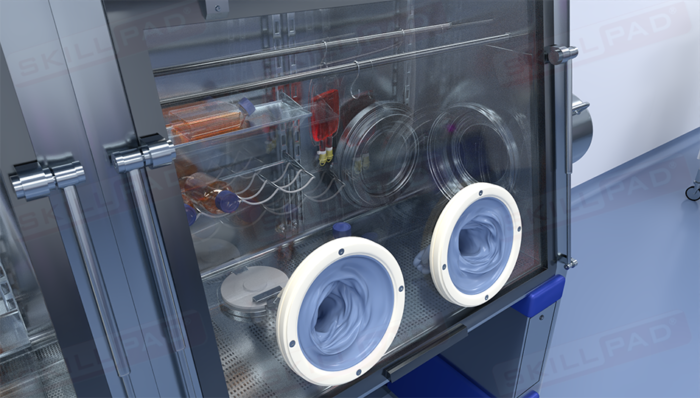

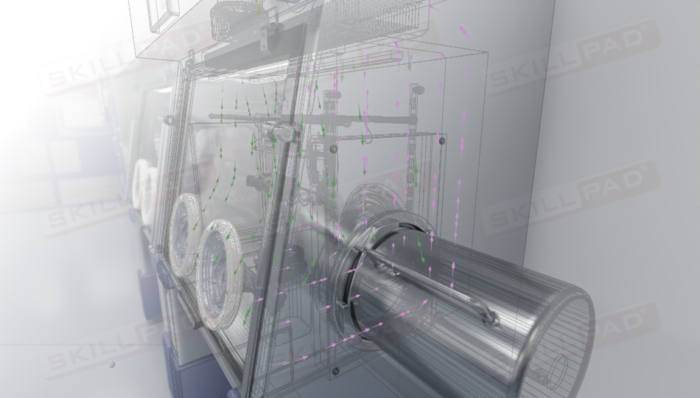

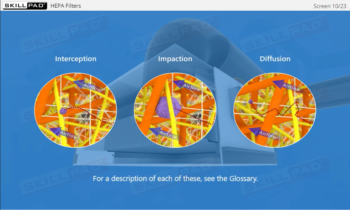

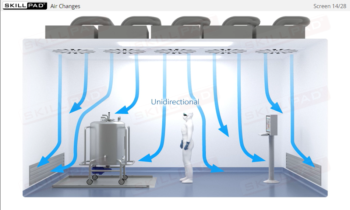

A detailed look at the use of closed isolators in aseptic processing of sterile products, covering their design, operating principles, and critical role in contamination control. This module explores how isolators maintain a sterile environment using HEPA filtration, positive pressure, and controlled airflow. Learners will gain practical knowledge of essential procedures, including preparation, aseptic manipulations, material transfers, and decontamination, ensuring proper use and regulatory compliance. Engaging interactive elements, including 3D simulations and scenario-based learning, reinforce best practices for working within an isolator.

Description

- Comprehensive Knowledge of Closed Isolators

Gain a deep understanding of closed isolators, their components, and their function in aseptic processing to maintain sterility and ensure product integrity.

- Critical Insights into Contamination Control

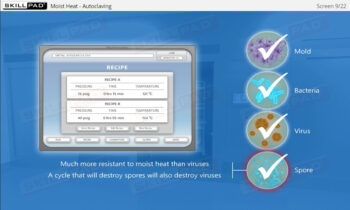

Learn how HEPA filtration, unidirectional airflow, and positive pressure work together to prevent microbial contamination, ensuring compliance with stringent regulatory standards.

- Proficiency in Aseptic Technique and Best Practices

Develop essential skills for working within an isolator, including proper glove use, material transfers, and aseptic manipulations—all reinforced through interactive 3D simulations and real-world scenarios.

- Confidence in Preparation and Decontamination Procedures

Understand the critical steps for preparing an isolator, from verifying equipment status to implementing personal protective measures. Learn decontamination procedures that maintain sterility for successive operations, reducing contamination risks.

- Interactive and Applied Learning

Engage with hands-on learning experiences, including guided discovery activities, real-time decision-making exercises, and knowledge checks to reinforce key concepts and best practices.