Bioreactors in Bioprocessing

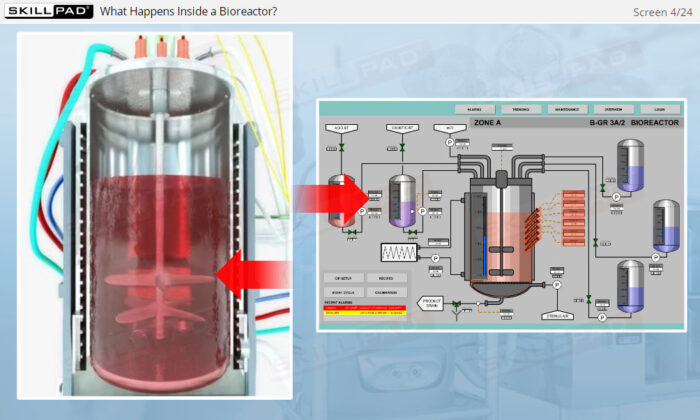

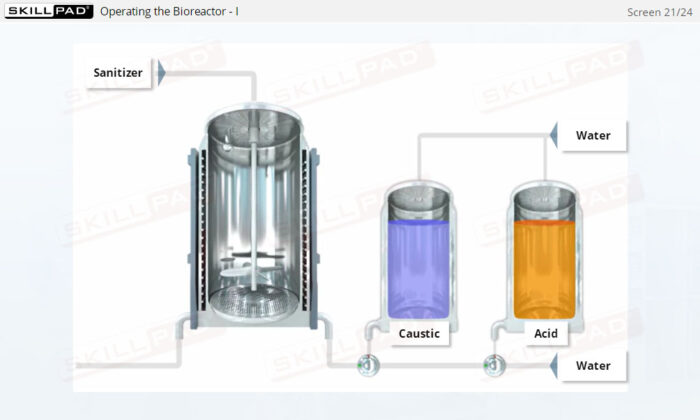

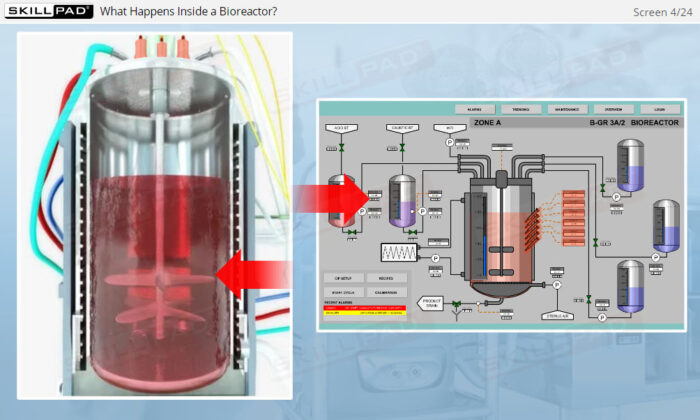

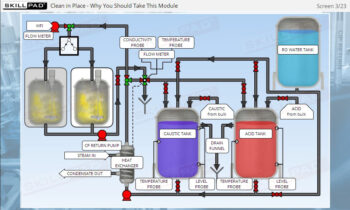

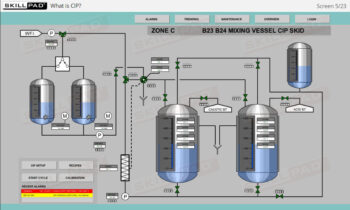

Describes the function, design, set-up and control of bioreactors in the biopharmaceutical industry. It examines control parameters such as heat management, pH, oxygen, mass transfer, and agitation, and how the type of cells being produced impacts on bioreactor set up and control. It also introduces the meaning of sterility, and bioreactor cleaning using CIP.

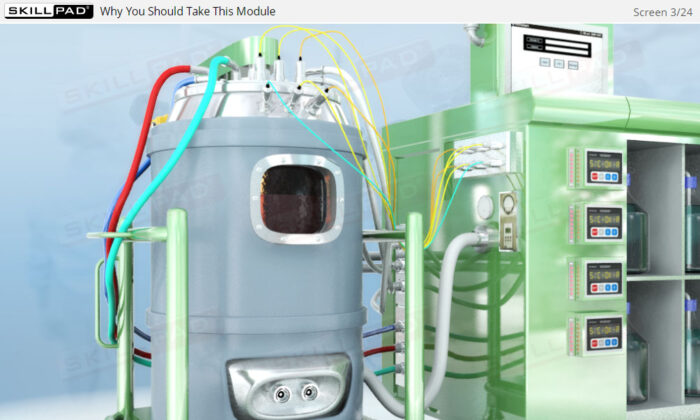

Whether for onboarding or annual refresher training, this Module is seamlessly deployable on any LMS and can be tailored to your company’s exact needs.

Duration: 30 Mins

Grade: Premium Performance

Description

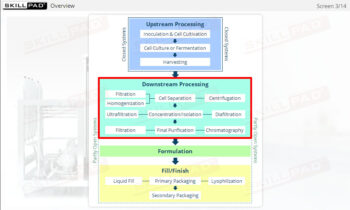

- Develop a foundational understanding of the purpose and functions of bioreactors in bioprocessing, including their design, operation, and the types of products they produce.

- Learn about the different types of bioreactors, their components, and the operating modes used to achieve optimal bioprocessing conditions, including batch, continuous, and fed-batch operations.

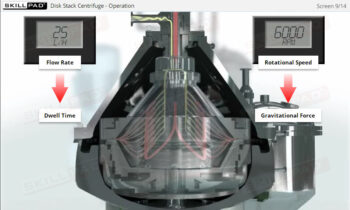

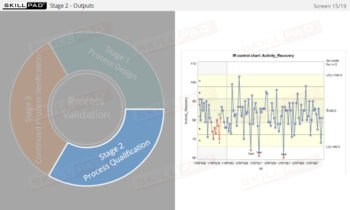

- Understand the process parameters that are critical for bioreactor operation, such as temperature, pH, dissolved oxygen, and mixing and how these parameters are monitored and controlled to ensure product quality and consistency.

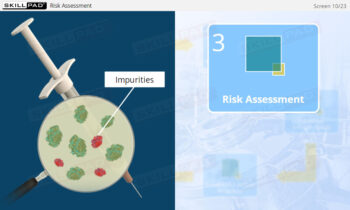

- Identify the risk factors that can compromise bioreactor sterility and learn strategies for preventing contamination, including Clean in Place (CIP) and Steam in Place (SIP) procedures.

- Explore the concepts of mixing and mass transfer within bioreactors and their impact on product yield and quality.

Learning Objectives

- Describe the purpose of a bioreactor in bioprocessing.

- Describe the structure of a typical stainless steel bioreactor.

- Distinguish between the different operating modes of a bioreactor.

- Explain how effective mixing can be achieved in a bioreactor.

- List the process parameters that are typically monitored and controlled when operating a bioreactor.

- Describe the various risk factors that can compromise bioreactor sterility and how contamination of a bioreactor can be prevented.

- Explain the concept of ‘mass transfer’ in bioprocessing.

- Explain the relationship between metabolism, heat generation, and agitation in bioprocessing.

Module Features

Animations

Voice Over

Knowledge Checks

Assessments

SCORM/AICC compatible

Full Screen