Blending

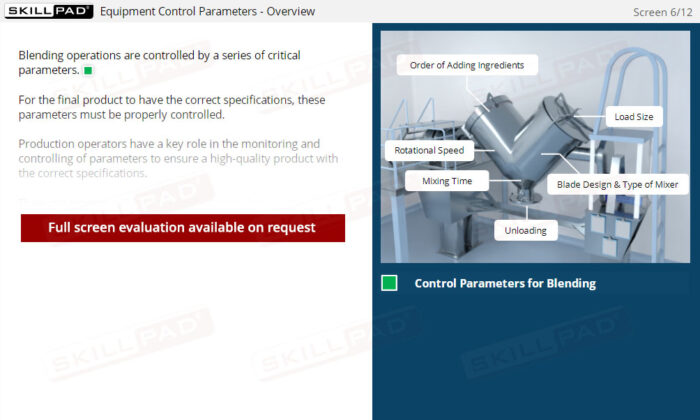

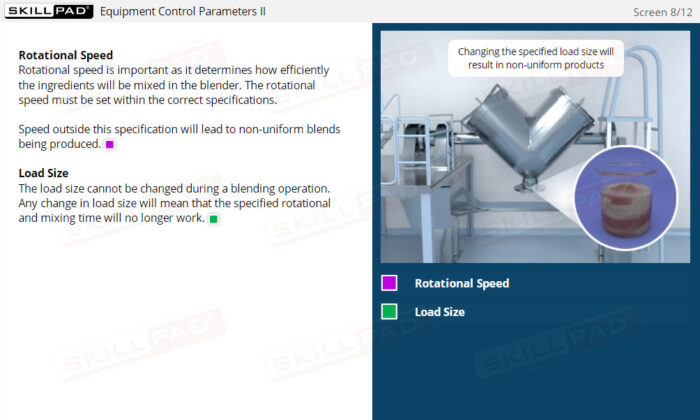

An overview of the blending process in solid dose manufacturing, detailing its purpose, equipment, and the steps involved in creating a uniform blend. This module explains the key parameters for controlling the process, common blending equipment such as V-blenders and ribbon blenders, and the safety precautions necessary when working with blenders. Learners will explore the function of critical parameters, such as mixing time, rotational speed, ingredient order, and load size, to ensure consistent and high-quality blends.

Whether for onboarding or annual refresher training, this Module is seamlessly deployable on any LMS and can be tailored to your company’s exact needs.

Duration: 30 Mins

Grade: Core Library

Description

- Learn the Purpose of Blending in Manufacturing: Understand the purpose of blending and how it ensures uniformity in solid dose products.

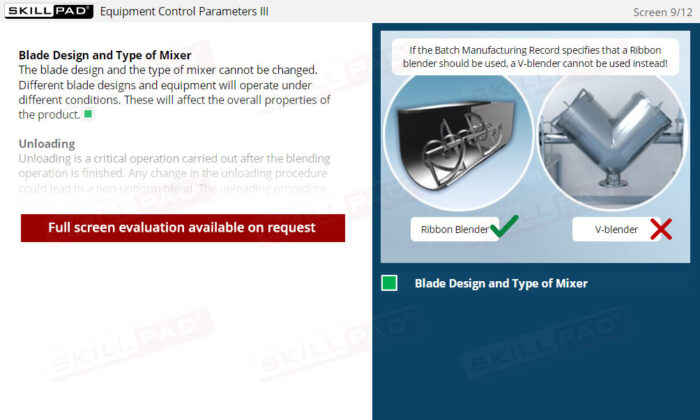

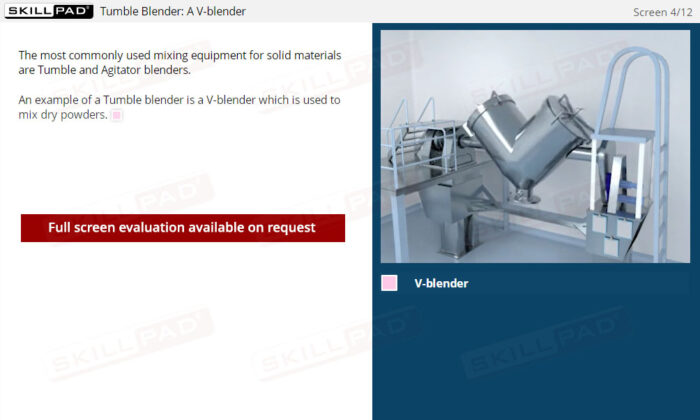

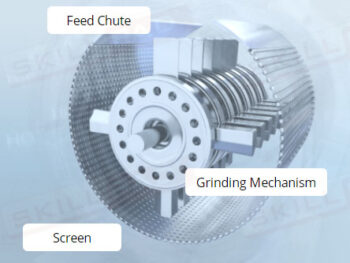

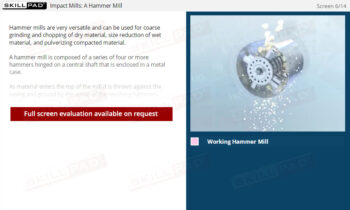

- Understand Common Blending Equipment: Learn about the design and operation of V-blenders and ribbon blenders, and their roles in the blending process.

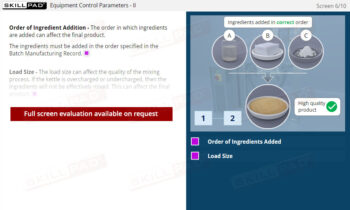

- Learn About Control Parameters: Gain foundational knowledge of critical blending parameters, such as ingredient order, mixing time, rotational speed, and load size, to maintain consistency and quality.

- Build Safety Awareness: Learn essential safety measures, including proper use of personal protective equipment (PPE) and equipment-specific safety procedures, to prevent accidents during blending operations.

Learning Objectives

- Explain the purpose of a blending operation.

- Name two commonly used blender types.

- Describe the structure of a ribbon blender.

- List the key parameters that must be controlled in a blending operation.

- Describe the precautions that should be taken when unloading and transporting blends.

- List typical PPE worn when working with blenders.

- Describe the safety precautions required when operating an cleaning a V-blender.

Keywords

- Blending Operations

- Solid Dose Manufacturing

- V-Blender

- Ribbon Blender

- Control Parameters

- Mixing Uniformity

- Rotational Speed

- Mixing Time

- Personal Protective Equipment (PPE)

- Safety Precautions

Module Features

Animations

Voice Over

Knowledge Checks

Assessments

SCORM/AICC compatible

Full Screen