Chemical Reactor Design

An exploration of the design and operational principles of chemical reactors used in the production of Active Pharmaceutical Ingredients (APIs). This module focuses on key aspects of reactor construction, including materials, auxiliary equipment, nitrogen atmosphere management, and mixing mechanisms. It also covers the importance of temperature control, reaction monitoring, and the role of various probes to ensure consistent and safe operations in the reactor environment.

Whether for onboarding or annual refresher training, this Module is seamlessly deployable on any LMS and can be tailored to your company’s exact needs.

Duration: 30 Mins

Grade: Core Library

Description

- Gain a Comprehensive Understanding of Reactor Design: Learn the fundamental purpose and structure of chemical reactors, including key materials used in their construction and the role of auxiliary equipment.

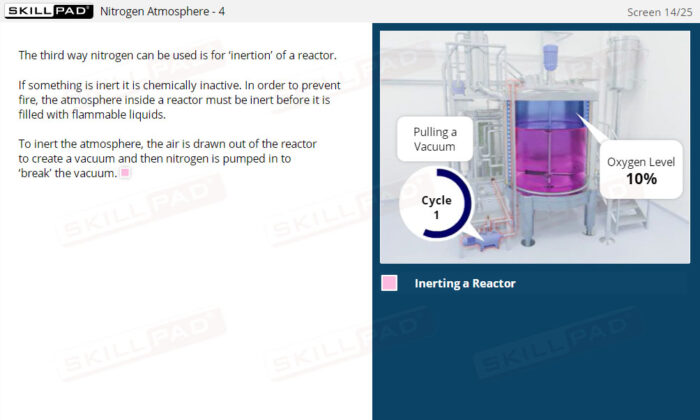

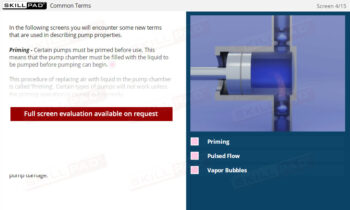

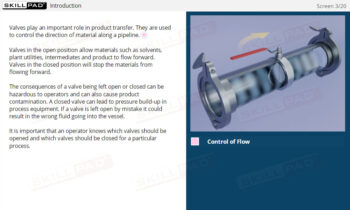

- Improve Process Efficiency and Safety: Understand critical safety practices, such as nitrogen inerting, vacuum application, and temperature control, to minimize operational risks in reactor-based processes.

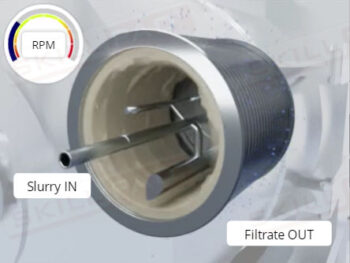

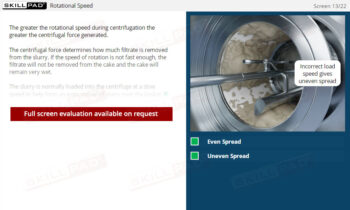

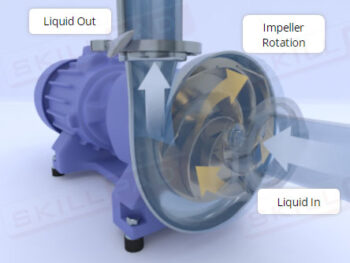

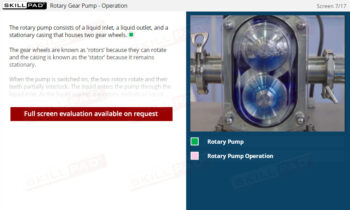

- Enhance Technical Knowledge of Mixing and Monitoring: Develop knowledge of impeller types, mixing mechanisms, and the function of baffles to optimize reaction conditions, while learning how to monitor reactions using various probes.

- Apply Practical Knowledge to Real-World API Manufacturing: Recognize how heating, cooling, agitation, and process monitoring are integrated into chemical reactor operations to ensure consistent product quality and regulatory compliance.

- Support Compliance with Industry Standards: Gain insights into reactor design principles that align with Good Manufacturing Practices (GMP) for safe, effective, and compliant pharmaceutical production.

Learning Objectives

- Describe the purpose of a chemical reactor.

- List three materials used in reactor construction.

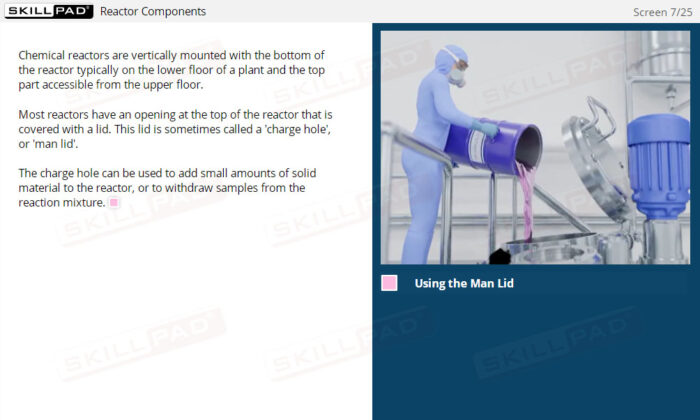

- Describe the common auxiliary equipment and connections found in a reactor.

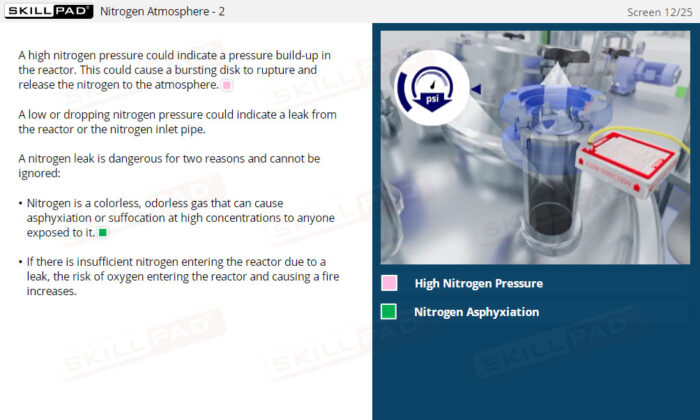

- Describe three different ways of using nitrogen atmosphere in a chemical reactor.

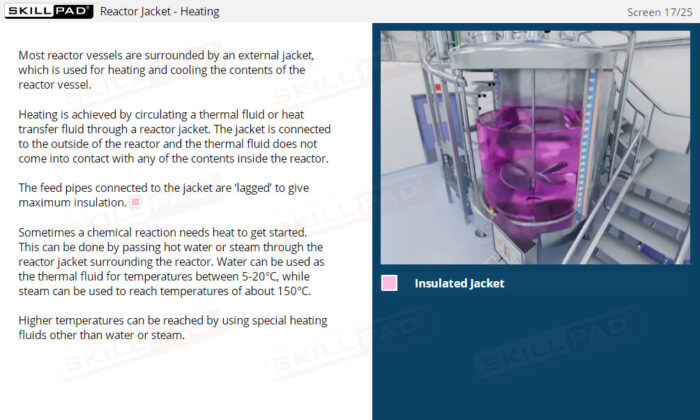

- Describe how reactors are heated and cooled.

- Name three impeller types and their associated mixing mechanisms.

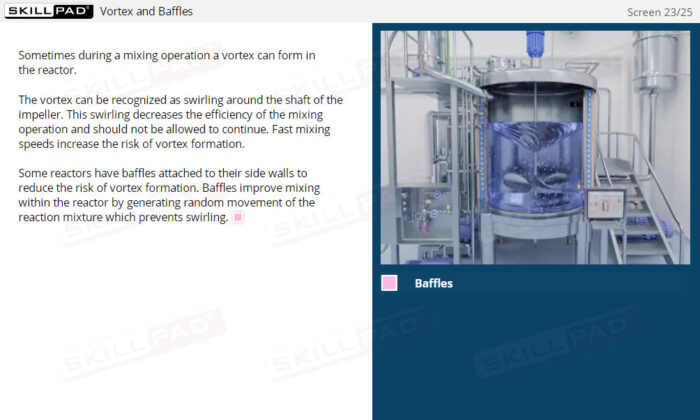

- Explain the purpose of baffles in a reactor.

- List three uses of probes in reaction monitoring.

Keywords

- Active Pharmaceutical Ingredients (API)

- Agitators

- Baffles

- Chemical Reactions

- Conductivity Probe

- Crystallization

- Glass

- Heating

- Impeller

- Inlet and Outlet Pipelines

- Maintenance

- Mixing

- Nitrogen Atmosphere

- Operation

- Pressure

- Probes

- Reactors

- Reactor Jacket

- Temperature

- Thermal Fluid

- Turbines

- Vacuum Line

- Vacuum

- Work-Up

Module Features

Animations

Voice Over

Knowledge Checks

Assessments

SCORM/AICC compatible

Full Screen