Cleanrooms: Rules, Control Parameters, and Testing

Rules, control parameters, and testing methods for cleanrooms used in pharmaceutical and biologics manufacturing facilities. It covers good housekeeping rules, manual testing needs, and process simulation in cleanroom monitoring.

Whether for onboarding or annual refresher training, this Module is seamlessly deployable on any LMS and can be tailored to your company’s exact needs.

Duration: 30 Mins

Grade: Core Library

Description

- Gain a comprehensive understanding of cleanroom rules and parameters.

- Learn about the importance of maintaining a cleanroom environment and the consequences of not following procedures.

- Understand the various instruments used in a cleanroom and their purpose.

- Develop skills to manually check cleanroom parameters.

- Understand the role of process simulation in cleanroom monitoring.

Learning Objectives

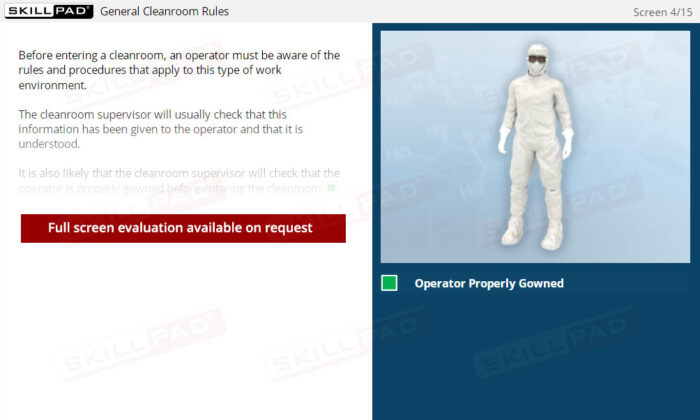

- List items that are typically not allowed in a cleanroom environment.

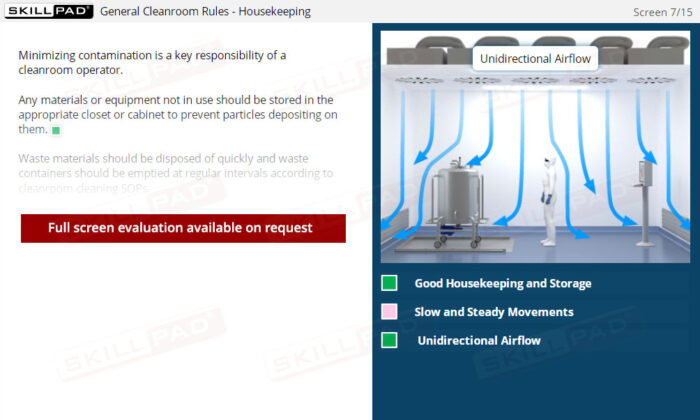

- Describe the good housekeeping rules that should be followed in a cleanroom.

- Explain why manual testing is needed in a cleanroom.

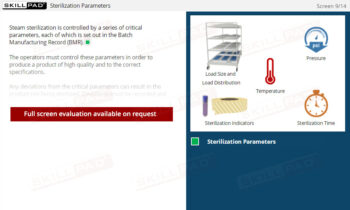

- List typical cleanroom parameters that are controlled and monitored.

- Name the instruments used to manually check cleanroom parameters.

- Explain the purpose of process simulation in cleanroom monitoring.

Keywords

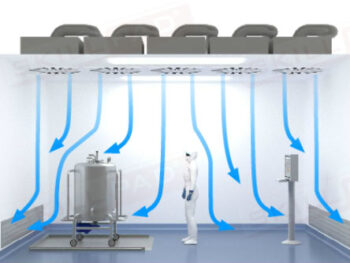

- Airflow

- Air Pressure

- Anemometer

- Automatic Monitoring

- Cleanroom

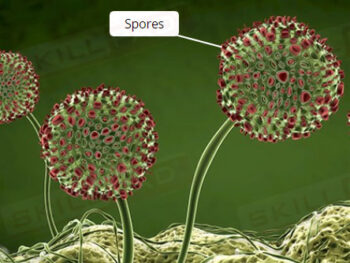

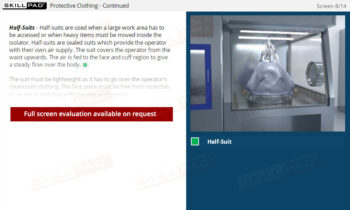

- Contamination

- Control Parameters

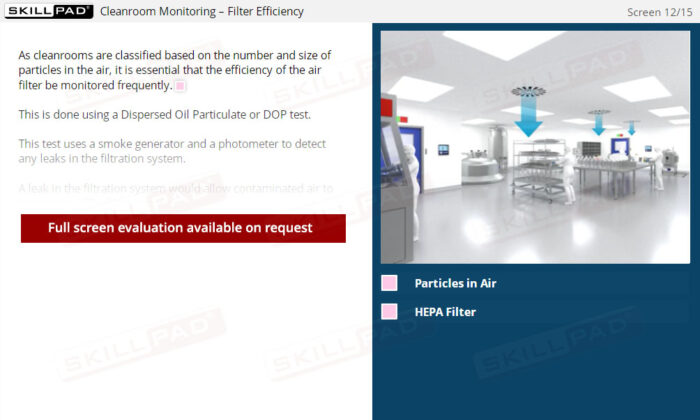

- Dispersed Oil Particulate Test

- Discrete Particle Counter

- DOP Test

- Filter Efficiency

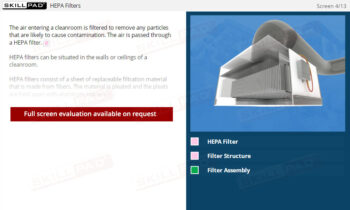

- HEPA Filter

- Humidity Hygrometer Manometer

- HVAC System

- Manual Testing

- Microbial Testing

- Particulate Count

- Particulate Size

- Pressure

- Testing

- Temperature

- Thermometer

- Rules

Module Features

Animations

Voice Over

Knowledge Checks

Assessments

SCORM/AICC compatible

Full Screen