Dryers

Introduction to the use of dryers in API manufacturing, with a focus on Tray Dryers and the critical parameters involved in their operation. It covers the purpose of drying, the structure and function of fixed bed dryers, and key factors such as temperature, humidity, airflow rate, and load size. The module explains how these parameters influence product quality and safety. Additionally, learners will explore the Personal Protective Equipment (PPE) required when working with dryers to support operator safety and product integrity.

Whether for onboarding or annual refresher training, this Module is seamlessly deployable on any LMS and can be tailored to your company’s exact needs.

Duration: 30 Mins

Grade: Core Library

Description

- Understand the Role of Drying in Pharmaceutical Processing: Learn about the purpose and importance of drying, including its role in supporting product stability, preventing degradation, and controlling microbial growth.

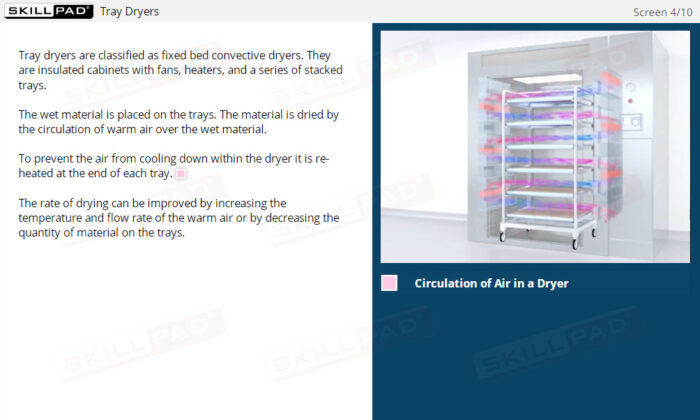

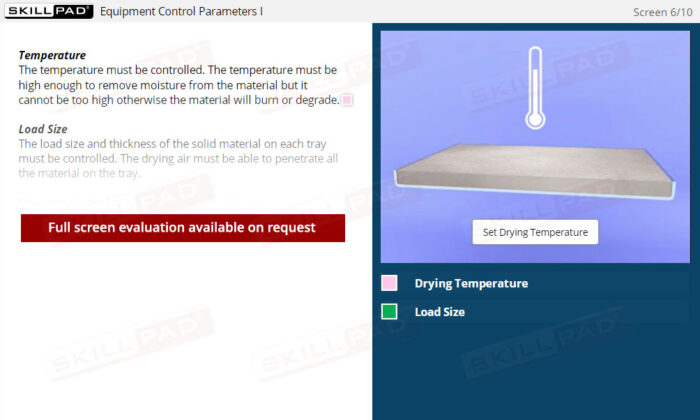

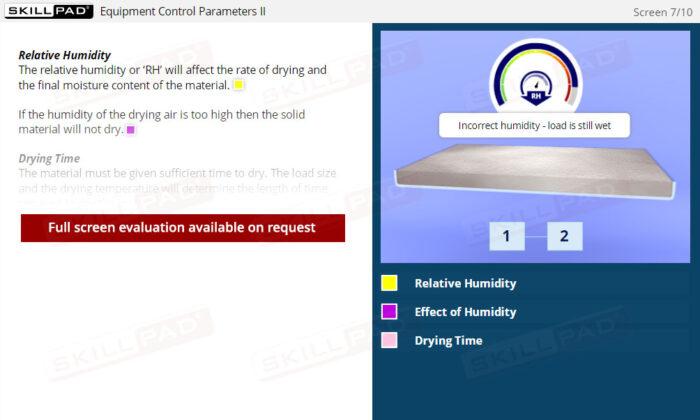

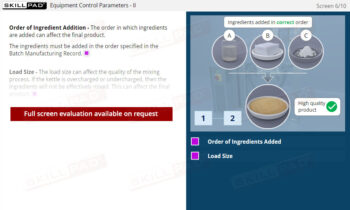

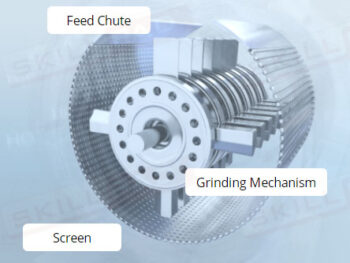

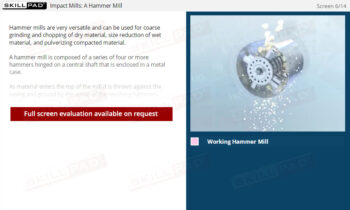

- Learn How Tray Dryers Work: Discover the structure and operation of Tray Dryers, and understand how key factors like temperature, humidity, airflow, and load size affect the drying process.

- Manage Critical Drying Parameters: Gain practical knowledge on how to monitor and control important drying parameters to help ensure consistent, high-quality products that meet pharmaceutical standards.

- Follow Safety Precautions When Using Dryers: Learn the importance of wearing appropriate PPE and following safety protocols to help prevent contamination and protect operators from risks such as burns and back injuries.