Drying

Exploration of the critical process of drying in API (Active Pharmaceutical Ingredient) manufacturing, focusing on the removal of moisture from solid products using various drying equipment. It covers the reasons for drying, its importance in maintaining product stability, and the control parameters that influence the drying process. Participants will learn about different types of drying equipment and how variables like load size, temperature, relative humidity, airflow rate, and drying time affect the quality and safety of the final product.

Whether for onboarding or annual refresher training, this Module is seamlessly deployable on any LMS and can be tailored to your company’s exact needs.

Duration: 30 Mins

Grade: Core Library

Description

- Recognize the Importance of the Drying Process: Understand why drying is essential in API manufacturing, including its role in removing solvents and preventing contamination or degradation of the product.

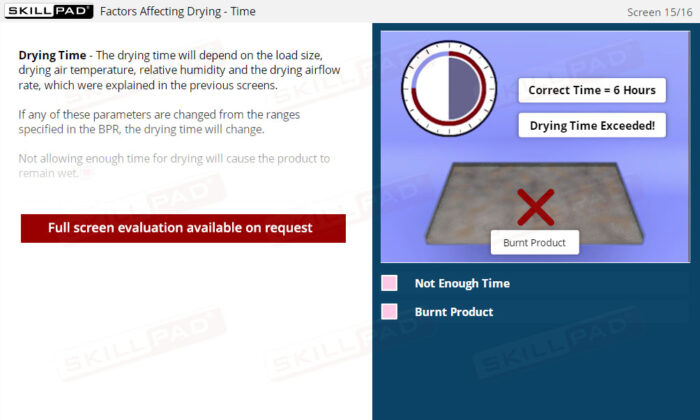

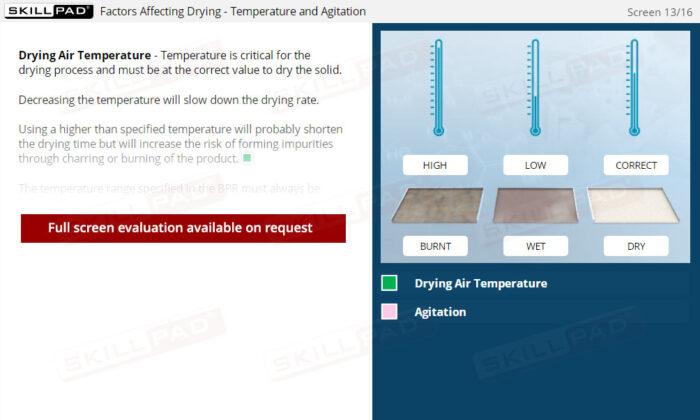

- Manage Critical Drying Parameters: Identify key control parameters such as temperature, relative humidity, airflow, and drying time, and understand how they impact the effectiveness of the drying process.

- Explore Different Types of Drying Equipment: Learn about drying equipment commonly used in API plants, including filter dryers, pan dryers, conical screw dryers, and fluidized bed dryers, and see how each contributes to the drying process.

- Control Key Process Variables: Manage variables like load size and airflow rate to ensure the drying process follows the specifications outlined in the Batch Production Record (BPR), supporting optimal product quality and safety.

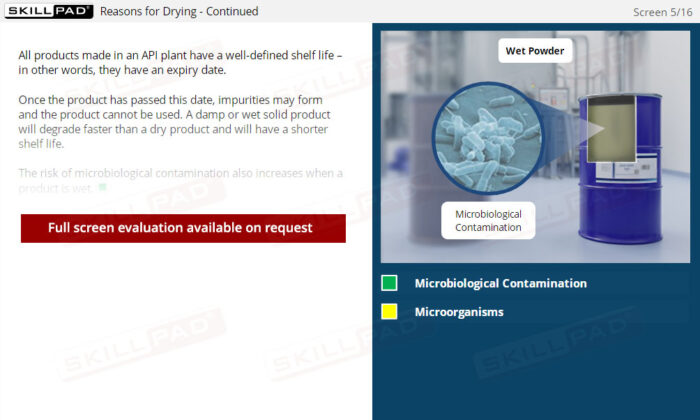

- Ensure Product Stability and Safety: Understand how drying helps maintain product shelf life and prevent microbiological contamination, equipping you with the knowledge to support the production of safe and effective pharmaceutical products.

Learning Objectives

- Explain the term ‘drying’ as it relates to API manufacturing.

- Explain the reasons for drying API products.

- Explain the term ‘Relative Humidity’ and its importance in a drying process.

- List examples of the types of drying equipment used in API plants.

- List and describe the importance of the parameters that affect a drying process.

Keywords

- Active Pharmaceutical Ingredient (API)

- Airflow Rate

- Agitation

- Burn

- Contamination

- Crystallization

- Degradation

- Drying

- Evaporation

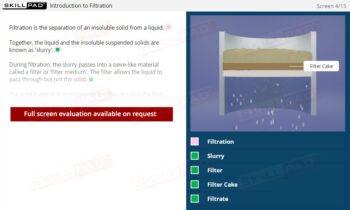

- Filter

- Fluidized Bed

- Heat

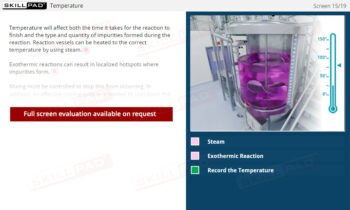

- Impurities

- Load Size

- Pan Dryer

- Product Stability

- Relative Humidity

- Solvent

- Shelf Life

- Spin or Tumble Dryer

- Temperature

- Wet Solid

Module Features

Animations

Voice Over

Knowledge Checks

Assessments

SCORM/AICC compatible

Full Screen