Filtration

An introduction to the filtration process in API (Active Pharmaceutical Ingredient) manufacturing, covering the theory behind filtration, the equipment used, and key process parameters. Through interactive visuals and explanations, learners will explore how solids are separated from liquids, the different types of filtration equipment, and the critical parameters that influence the filtration process. The module also highlights the importance of drying products after filtration to ensure quality and meet product specifications.

Whether for onboarding or annual refresher training, this Module is seamlessly deployable on any LMS and can be tailored to your company’s exact needs.

Duration: 30 Mins

Grade: Core Library

Description

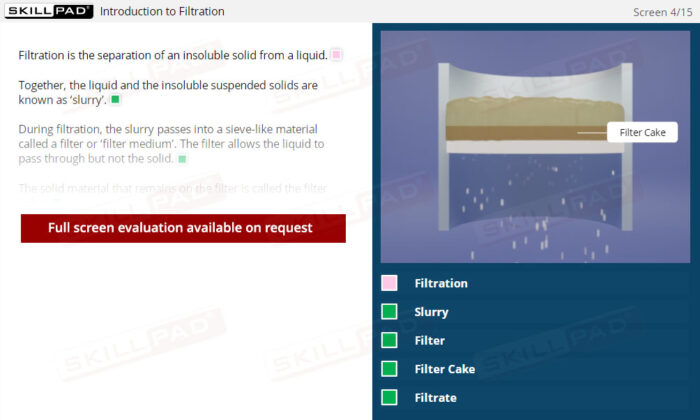

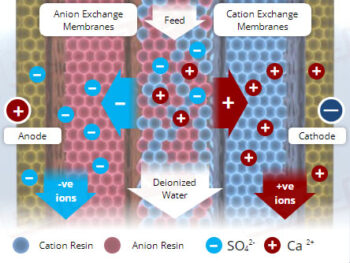

- Understand the Fundamentals of Filtration: Understand the basic process of filtration, including how solids are separated from liquids and the role of the filter medium in achieving effective separation.

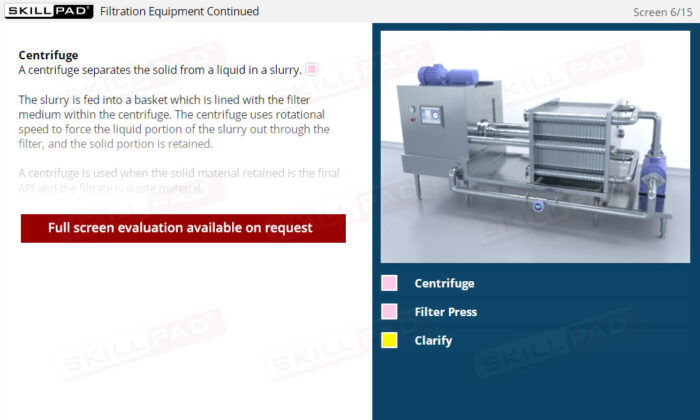

- Gain Knowledge of Filtration Equipment: Explore common filtration equipment, such as filter dryers, centrifuges, and filter presses, and understand their specific applications in API production.

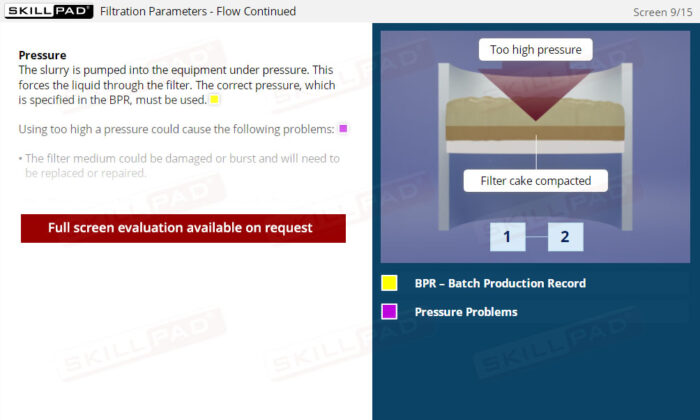

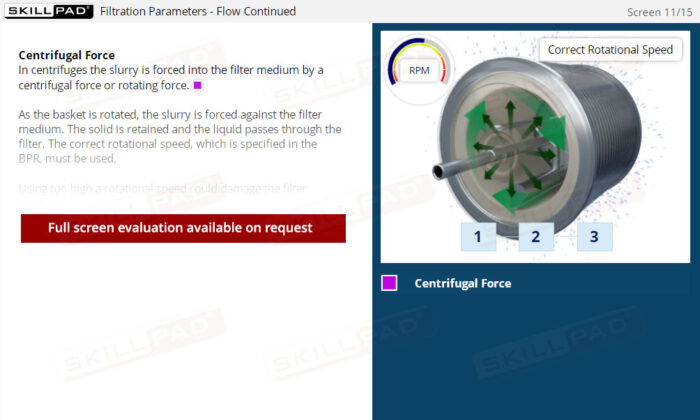

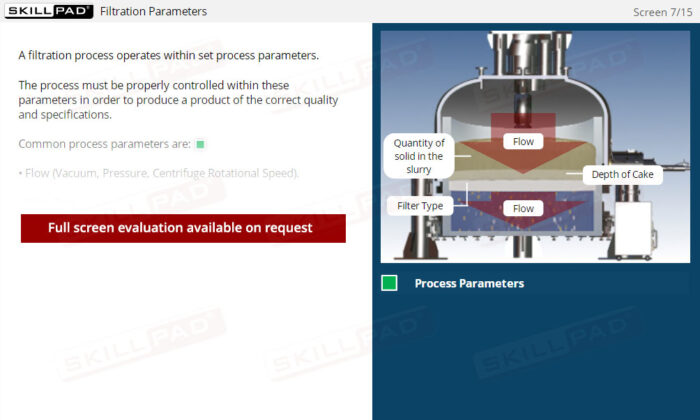

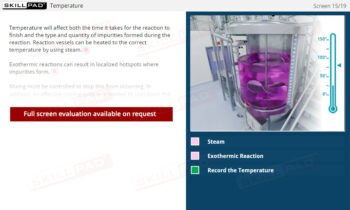

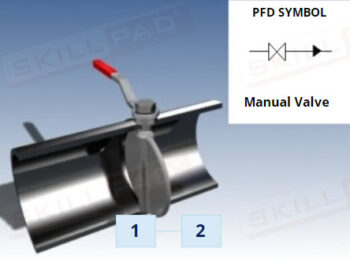

- Manage Key Filtration Parameters: Identify and control critical process parameters—such as pressure, vacuum, and centrifugal force—that affect filtration efficiency and product quality.

- Recognize the Importance of Drying After Filtration: Understand why drying is a crucial step after filtration to ensure that solid API products meet quality standards before packaging and distribution.

Learning Objectives

- Describe the process of filtration as it is used in API manufacturing.

- Name the commonly used equipment in a filtration process.

- List the main parameters that affect filtration.

- Explain the importance of drying products.

Keywords

- Active Pharmaceutical Ingredient (API)

- Cake Thickness

- Centrifuge

- Centrifugal Force

- Drying

- Filtration

- Filter Cake

- Filter Dryer

- Filter Press

- Filter Type

- Filter Medium

- Filtrate

- Filtration Equipment

- Filtration Process

- Flow Rate

- Parameters

- Pressure

- Product Quality

- Slurry

- Solids Separation

- Vacuum

- Wet Solids

Module Features

Animations

Voice Over

Knowledge Checks

Assessments

SCORM/AICC compatible

Full Screen