Filtration for Finished Dose

An overview of filtration in pharmaceutical manufacturing with a focus on the plate and frame filter press. Learn how this critical equipment separates solids from liquids, the key operational parameters to control during filtration, and essential safety precautions. This module also highlights the versatility of filter presses, their assembly, and the importance of proper maintenance and handling for ensuring product quality and operator safety.

Whether for onboarding or annual refresher training, this Module is seamlessly deployable on any LMS and can be tailored to your company’s exact needs.

Duration: 30 Mins

Grade: Core Library

Description

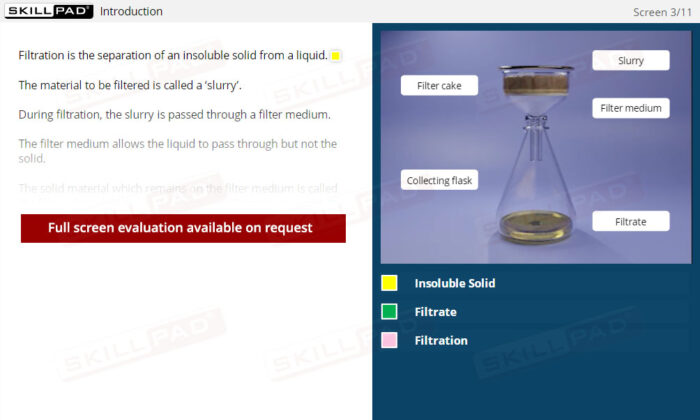

- Learn Filtration Principles: Learn the basic concept of filtration, including how solids are separated from liquids and the roles of slurry, filter medium, filter cake, and filtrate in the process.

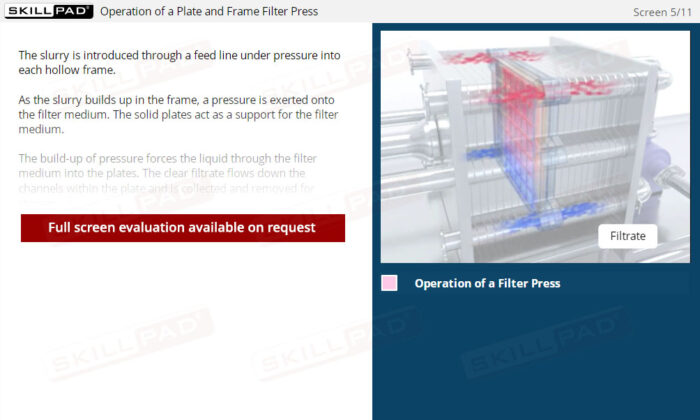

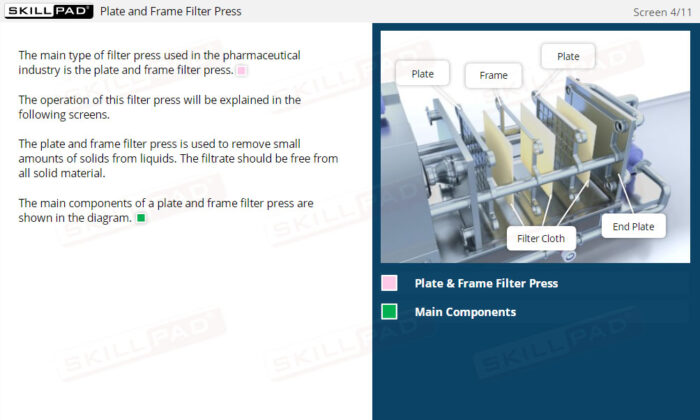

- Understand Plate and Frame Filter Press Operation: Gain foundational knowledge of the primary type of filter press used in the industry, including its components, operational mechanics, and benefits such as flexibility and ease of maintenance.

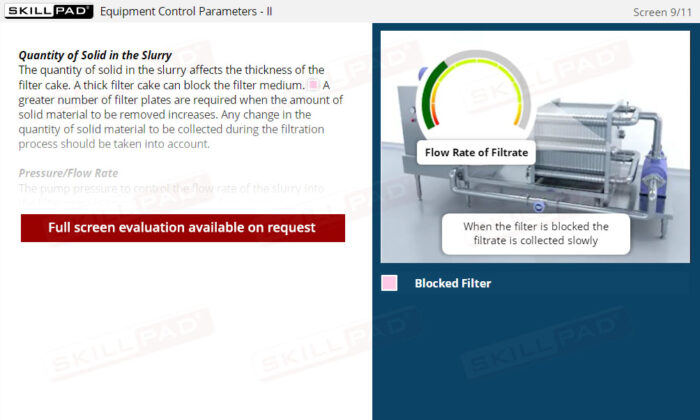

- Understand Operational Parameters: Understand the importance of managing key parameters, such as filter assembly, filter type, slurry composition, and pump pressure, to ensure consistent product quality.

- Recognize Safety Protocols: Learn about PPE requirements, ergonomic considerations, and safe handling practices to minimize risks during filter press operations.

- Develop Troubleshooting Skills: Identify and address common issues such as leaks, blockages, and improper assembly to maintain a smooth and efficient filtration process.

Learning Objectives

- Explain the purpose of filtration.

- Describe the main type of filter press used in the pharmaceutical industry.

- Explain how a filter press operates.

- List the parameters that must be controlled during the filtration process.

- Describe the safety precautions that need to be taken when operating a filter press.

Keywords

- Batch Manufacturing Record

- Contamination Prevention

- Filter Assembly

- Filter Cake

- Filter Medium

- Filter Press Operation

- Filtrate

- Filtration

- Frame

- GMP

- Knowledge Checks

- Maintenance

- Operational Parameters

- Personal Protective Equipment

- Plate and Frame Filter Press

- PPE

- Pressure Control

- Product Quality

- Pump Pressure

- Safety Precautions

- Slurry

- Solid Material

Module Features

Animations

Voice Over

Knowledge Checks

Assessments

SCORM/AICC compatible

Full Screen