Fluidized Beds

An overview of the fluidized bed granulation process, explaining its purpose, equipment, and the steps involved in forming granules. This module outlines key control parameters, the advantages of using fluidized beds, and the safety precautions necessary when operating this equipment. Learners will explore the function of critical components such as the air inlet, spray nozzles, and exhaust filters, and understand the importance of maintaining control over airflow, spray rate, and drying temperature to ensure consistent and high-quality granules.

Whether for onboarding or annual refresher training, this Module is seamlessly deployable on any LMS and can be tailored to your company’s exact needs.

Duration: 30 Mins

Grade: Core Library

Description

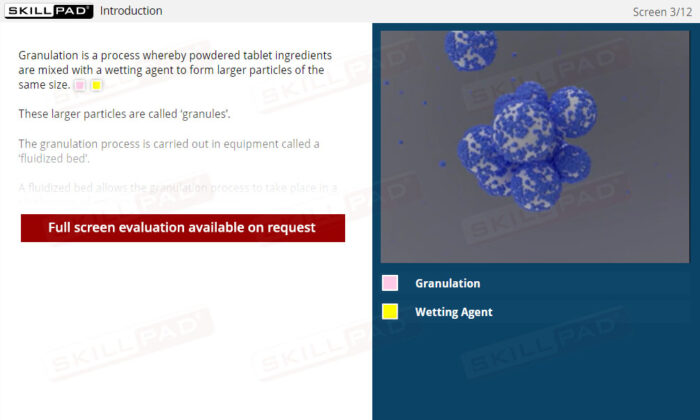

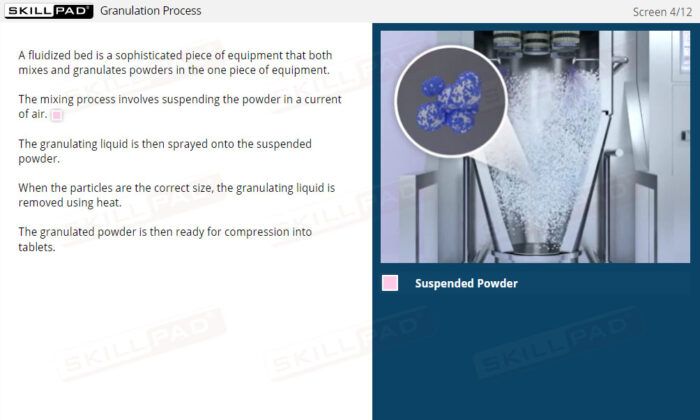

- Learn the Purpose of Granulation: Understand how fluidized beds enable efficient mixing and granulation within a single piece of equipment.

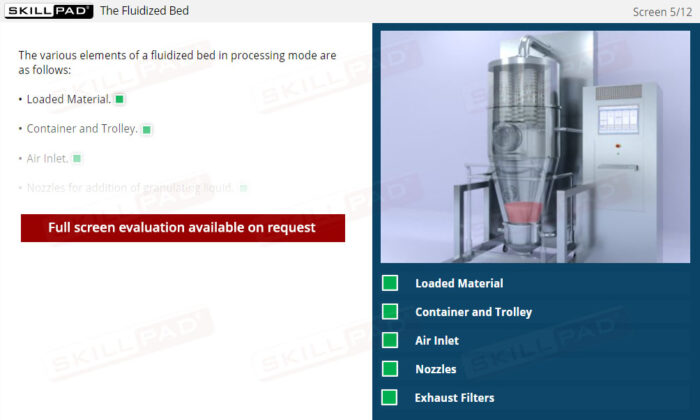

- Understand Equipment Components: Identify and describe the various parts of a fluidized bed granulator and their functions.

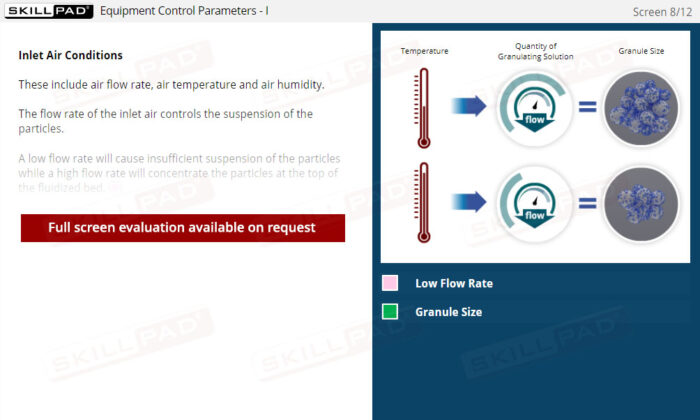

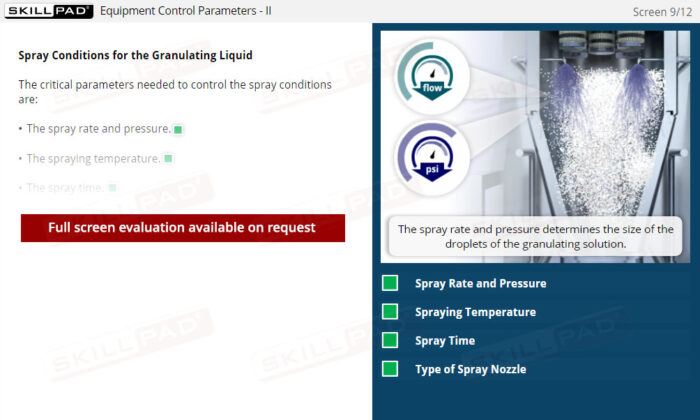

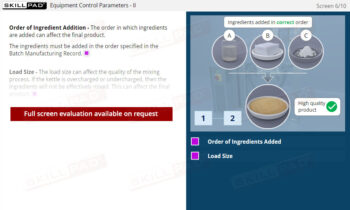

- Learn About Process Control: Gain foundational knowledge of critical control parameters, such as airflow rate, spray rate, and drying temperature, to ensure high-quality granules.

- Improve Operational Efficiency: Learn the operational steps needed to control the granulation process, from ingredient loading to drying.

- Prioritize Safety: Understand essential safety protocols, including proper use of personal protective equipment (PPE) when working with fluidized beds.

Learning Objectives

- Define the purpose of a granulation process.

- Explain the operating principles of a fluidized bed.

- Define the various components of a fluidized bed.

- List the processing steps involved in operating a fluidized bed.

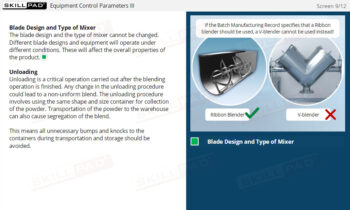

- Describe the key parameters that must be controlled in a fluidized bed process.

- List the typical PPE worn when working with fluidized beds.

Keywords

- Granulation Process

- Fluidized Bed Granulator

- Granulating Liquid

- Particle Suspension

- Control Parameters

- Inlet Air Flow

- Spray Nozzle

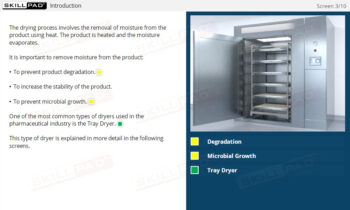

- Drying Temperature

- Mixing Efficiency

- Personal Protective Equipment (PPE)

Module Features

Animations

Voice Over

Knowledge Checks

Assessments

SCORM/AICC compatible

Full Screen