Gas Sterilization

Ethylene oxide (ETO) use in gas sterilization, covering applications, process, equipment, and critical sterilization parameters. It also explores the advantages of ETO sterilization and use of indicators for process monitoring.

Part of Annex 1 training requirements.

Whether for onboarding or annual refresher training, this Module is seamlessly deployable on any LMS and can be tailored to your company’s exact needs.

Duration: 30 Mins

Grade: Core Library

Description

- Gain a comprehensive understanding of the use of ethylene oxide (ETO) in gas sterilization, including the equipment used and operating parameters involved.

- Learn about the advantages and disadvantages of ETO sterilization.

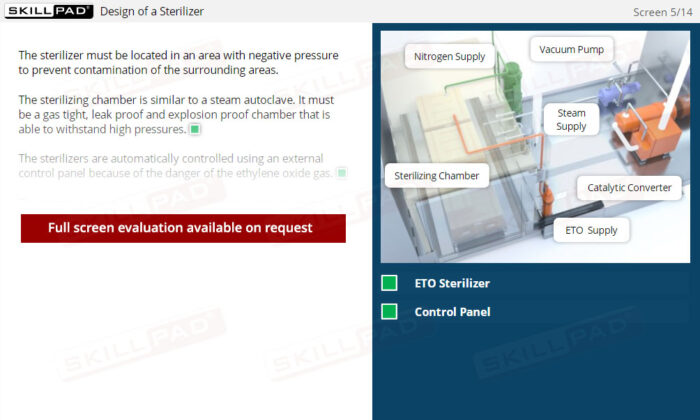

- Explore the structure of a typical ETO sterilizer and the stages of an ETO sterilization process.

- Appreciate the critical role of indicators in verifying that sterilization conditions are met in an ETO sterilization process.

Learning Objectives

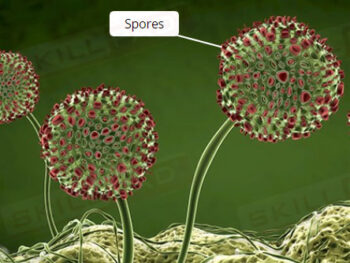

- Describe the applications of ethylene oxide (ETO) gas sterilization.

- List the advantages and disadvantages of ETO sterilization.

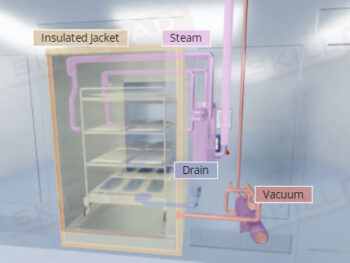

- Describe the structure of a typical ETO sterilizer.

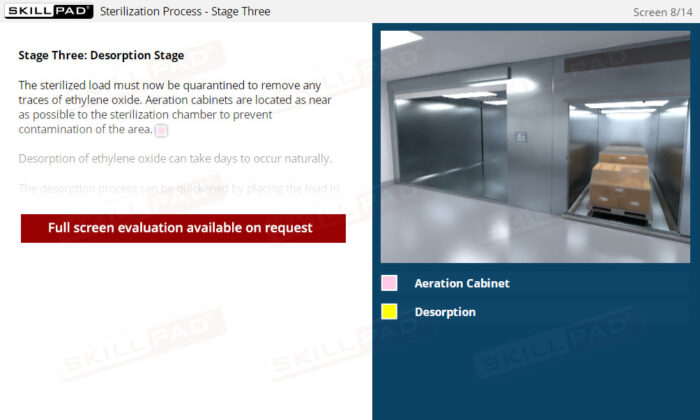

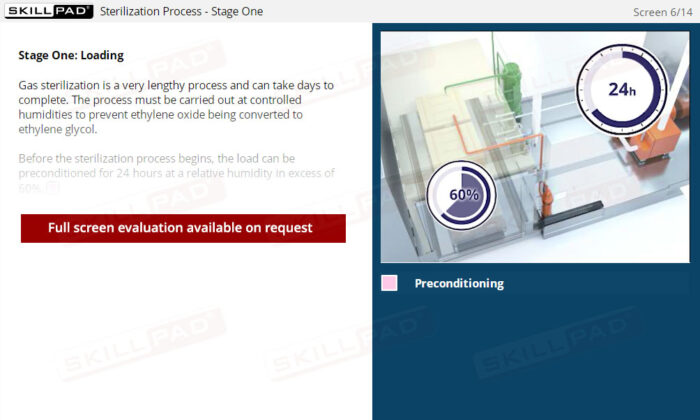

- Explain the three stages of an ETO sterilization process.

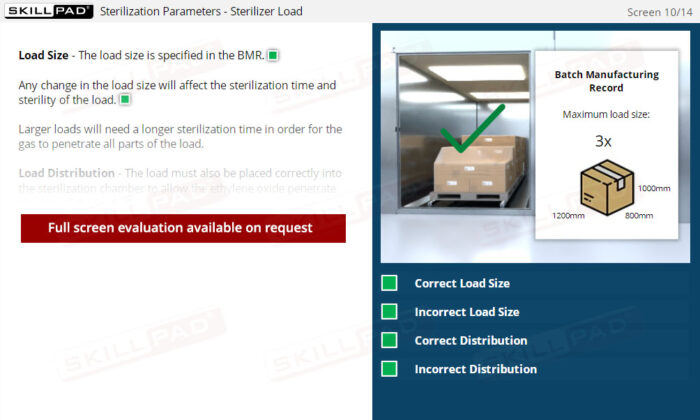

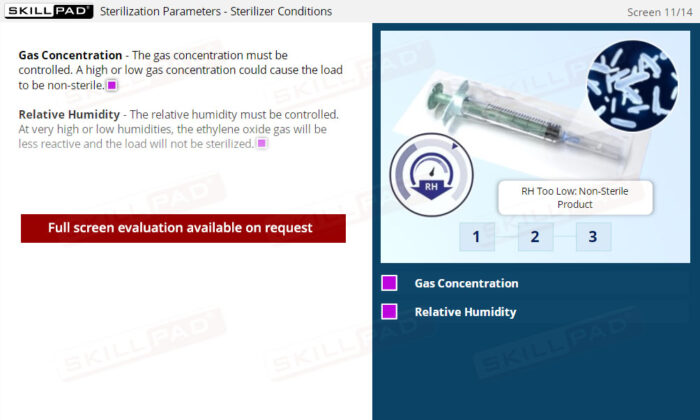

- List the critical parameters that must be monitored and controlled in an ETO process.

- Name the two indicators used to check if the sterilization conditions were reached in an ETO sterilization process.

Keywords

- Critical Sterilization Parameters

- Desorption

- Ethylene Oxide (ETO)

- Gas Sterilization

- Personal Protective Equipment

- Preconditioning

- Quarantine

- Relative Humidity

- Residues

- Sterilization Equipment

- Sterilization Procedures

- Sterilizing Chamber

Module Features

Animations

Voice Over

Knowledge Checks

Assessments

SCORM/AICC compatible

Full Screen