HPLC Troubleshooting

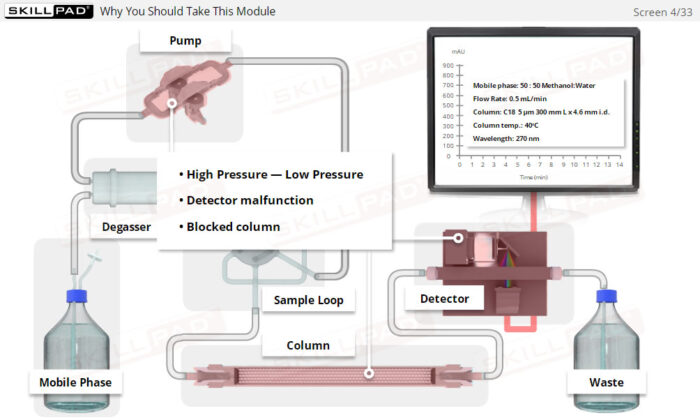

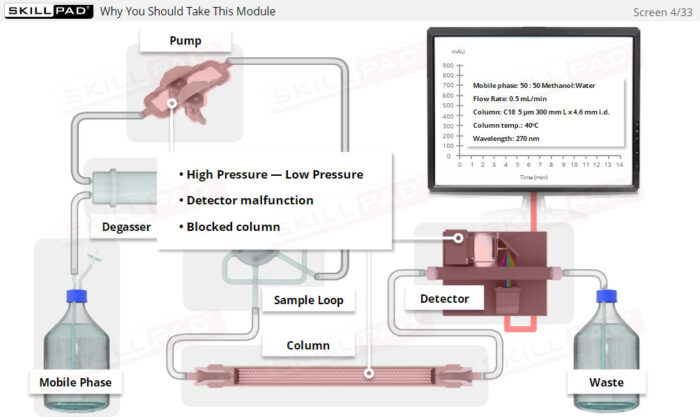

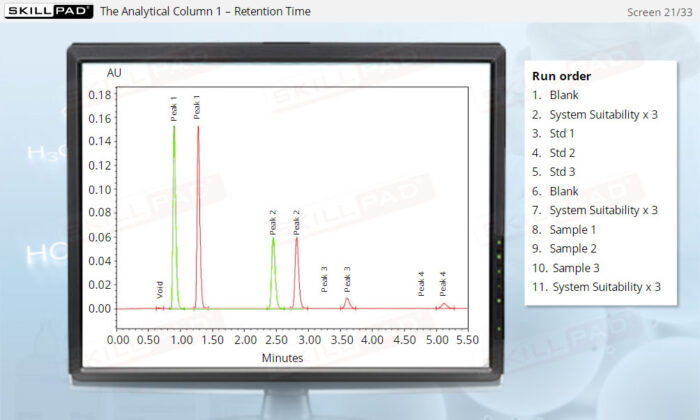

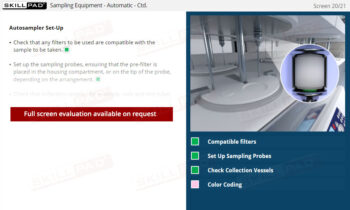

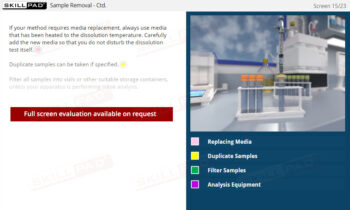

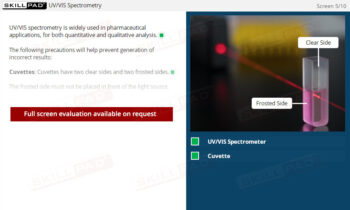

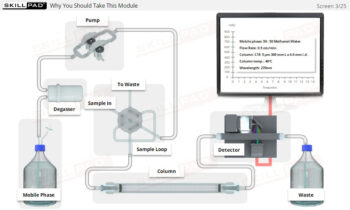

A comprehensive guide to efficiently diagnosing and resolving issues in High-Performance Liquid Chromatography (HPLC) systems. The module covers essential areas such as sample preparation, injector and needle performance, pump calibration, pressure inconsistencies, and column and detector maintenance. Learners will gain insights into minimizing disruptions and maintaining the accuracy and reliability of HPLC analyses, with clear explanations of preventative measures and troubleshooting techniques for common issues affecting baseline stability, peak shapes, and overall system performance.

Whether for onboarding or annual refresher training, this Module is seamlessly deployable on any LMS and can be tailored to your company’s exact needs.

Duration: 30 Mins

Grade: Premium Performance

Description

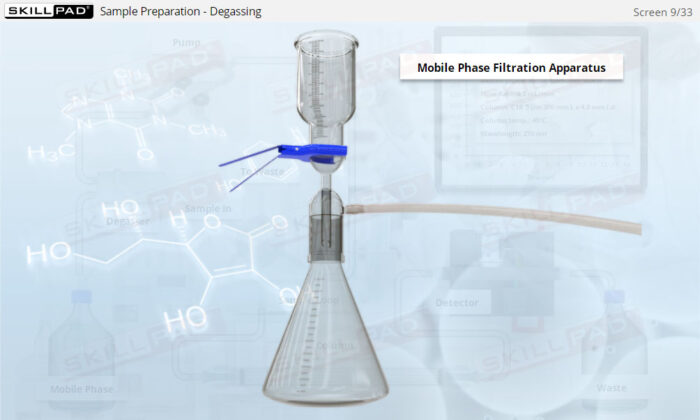

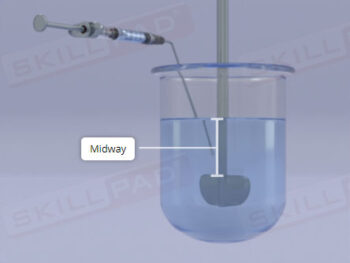

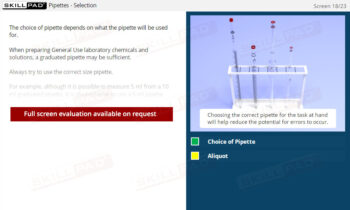

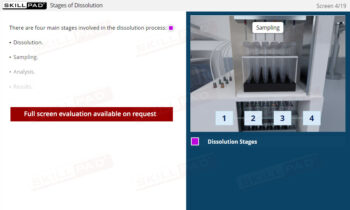

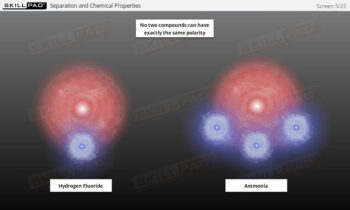

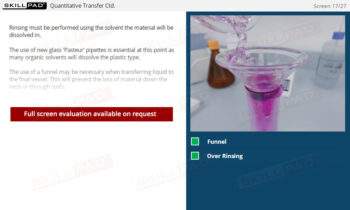

- Master Sample Preparation Techniques: Understand the critical role of complete dissolution, filtration, and degassing in ensuring accurate and reliable HPLC results, and learn best practices to prevent contamination and interference.

- Injector and Needle Optimization: Gain practical knowledge of how proper maintenance and blank injections can safeguard against performance issues, ensuring precise sample delivery.

- Pump Calibration and Pressure Management: Learn why regular pump calibration is crucial and acquire strategies for identifying and resolving both high and low-pressure problems, ensuring stable flow and optimal system performance.

- System Suitability Testing and Troubleshooting: Familiarization with the purpose of system suitability tests and how to interpret retention time shifts, resolve baseline noise, and troubleshoot column issues for better separation and peak resolution.

- Detect and Prevent Leaks and System Failures: Identify areas prone to leaks, such as columns, pumps, and detectors, and learn effective solutions to maintain the integrity of high-pressure connections.

- Prolong Column Life Through Best Practices: Discover proper storage and handling techniques to extend the lifespan of HPLC columns, minimizing the need for replacements and ensuring consistent, high-quality results over time.

Learning Objectives

- Explain why proper sample preparation is critical in HPLC and why degassing is performed.

- Explain how injector and needle performance can affect a HPLC analysis.

- Explain why HPLC system pumps must be calibrated.

- Describe the problems associated with pressure being too high or too low in HPLC and how these problems can be resolved.

- Explain the purpose of HPLC System Suitability testing.

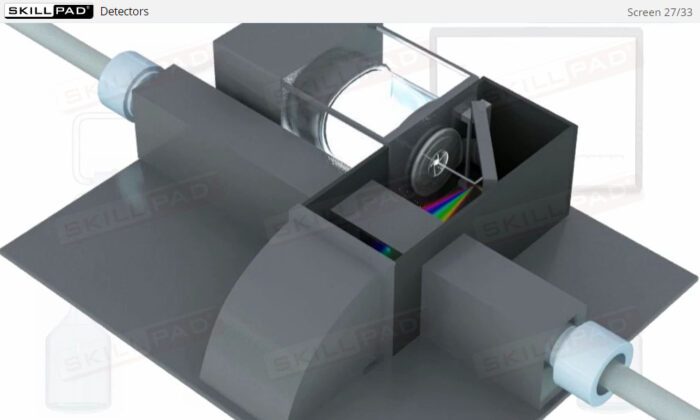

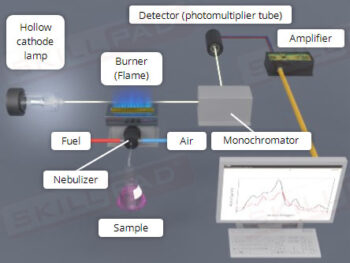

- Describe the most common problems affecting baseline, peak shape, and detectors, and how they can be resolved.

- List the areas of a HPLC system that can be affected by leaks.

- Describe the best practices for care of a HPLC column.

Keywords

- Baseline Stability

- Column Maintenance

- Degassing

- Detector Issues

- Dissolution

- Filtration

- High Pressure

- HPLC Troubleshooting

- Injector Performance

- Low Pressure

- Needle Maintenance

- Peak Shape

- Pump Calibration

- Retention Time

- Sample Preparation

Module Features

Animations

Voice Over

Knowledge Checks

Assessments

SCORM/AICC compatible

Full Screen