Milling

Introduces the milling process used in pharmaceutical manufacturing, focusing on particle size reduction techniques, equipment operation, and safety protocols. It explores different types of mills, including cutter mills and hammer mills, and explains their operating principles. Learners will understand key milling parameters that must be controlled to ensure product quality and explore the purposes of milling, such as improving solubility and enhancing blending. The module also highlights safety measures for working with milling equipment to prevent hazards associated with powder handling.

Whether for onboarding or annual refresher training, this Module is seamlessly deployable on any LMS and can be tailored to your company’s exact needs.

Duration: 30 Mins<br /> Grade: Core Library

Description

- Understand Particle Size Control: Gain a thorough understanding of the importance of achieving the correct particle size in milling operations to ensure product quality and avoid blending and compression issues.

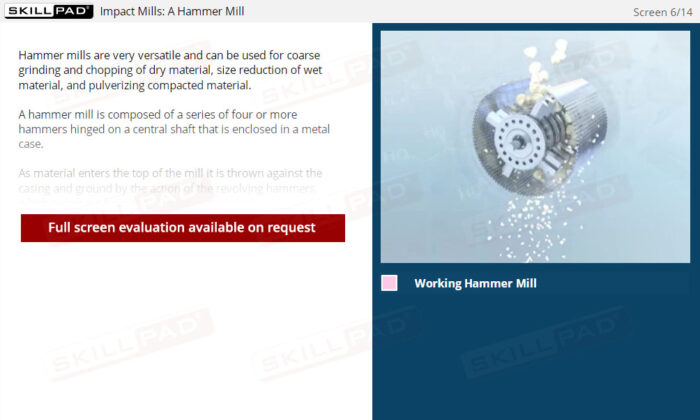

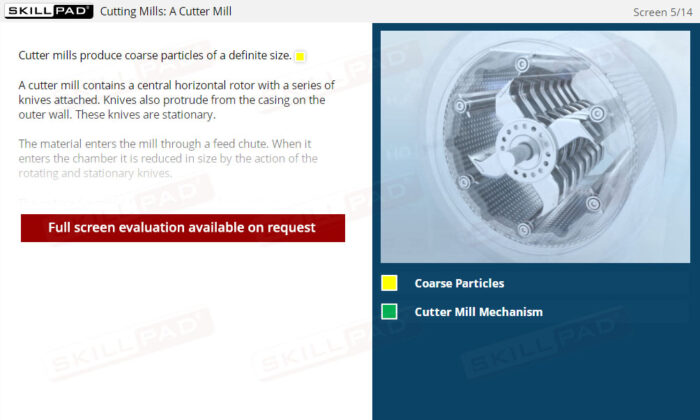

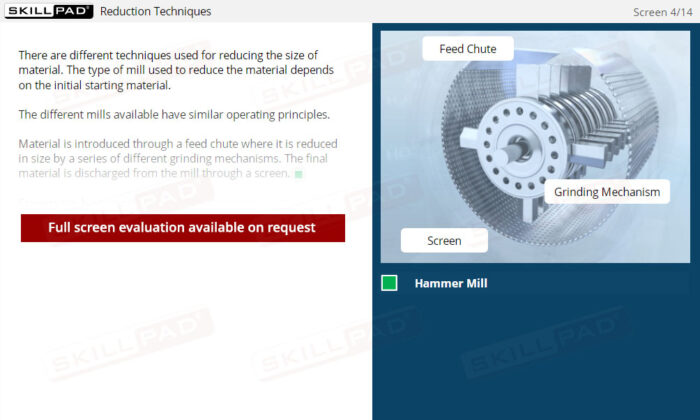

- Become Familiar with Milling Equipment Types and Operation: Learn about the basic operating principles of different milling equipment, including cutter mills and hammer mills, and how to select the appropriate mill for different materials.

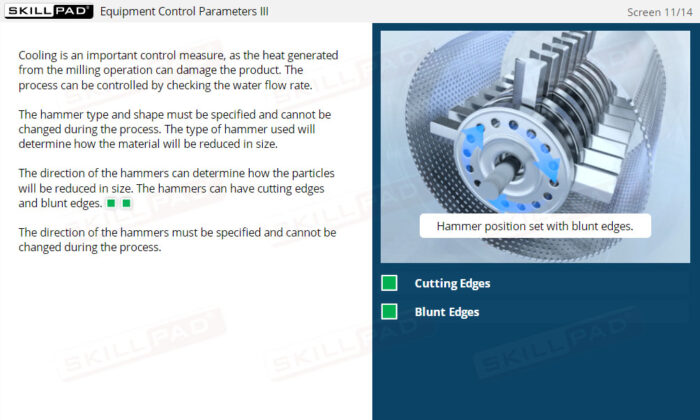

- Build Knowledge of Milling Parameters: Understand the critical parameters that must be controlled during milling operations, such as screen size, rotational speed, feed rate, and cooling, to meet product specifications.

- Gain Insights into Milling Purposes and Benefits: Explore the reasons behind milling, such as improving material solubility, increasing dissolution rates, and facilitating better mixing and blending of solid ingredients.

- Build Awareness of Safety Protocols: Learn the essential safety precautions when working with milling equipment, including the use of personal protective equipment (PPE) and handling powders to prevent health hazards such as respiratory issues and static ignitions.

Learning Objectives

- Explain why achieving the correct particle size is important.

- Describe the basic operating principles of a mill.

- Explain the difference between cutting mills and impact mills.

- Explain the reasons for milling.

- Name the key parameters that must be controlled in a milling operation.

- Explain why each key milling parameter must be controlled.

- Describe the safety precautions that must be followed when working with milling equipment.

Keywords

- Agitation and Mixing

- Aqueous Phase

- Cream Formulation

- Critical Parameters

- Hydrocarbon Phase

- Kettles</li>

- M

- ixing Process

- Personal Protective Equipment (PPE)

- Pharmaceutical Manufacturing

- Quality Control

- Semisolid Products

Module Features

Animations

Voice Over

Knowledge Checks

Assessments

SCORM/AICC compatible

Full Screen