Process Flow Diagrams

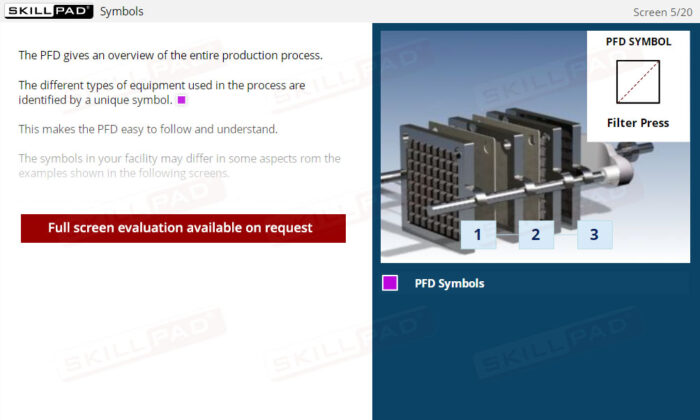

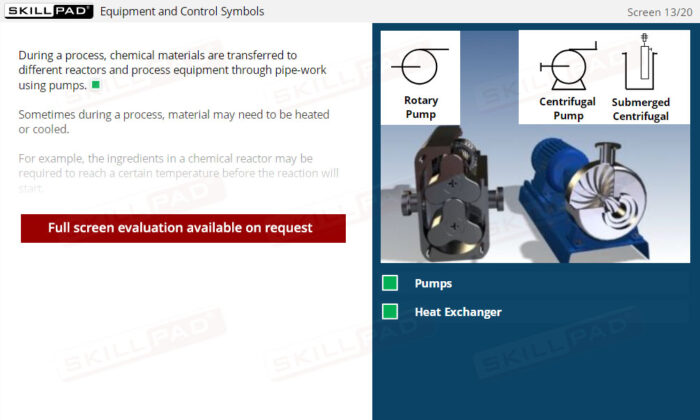

An introduction to Process Flow Diagrams (PFDs) used in the pharmaceutical and chemical industries to visually represent processes and equipment. This module covers the symbols used to depict key elements such as reactors, filters, pumps, gauges, and heat exchangers. Learners will explore the role of gauges, valves, and pipe-work in maintaining smooth operations, with a focus on interpreting basic PFDs and understanding the difference between manual and automatic control systems.

Whether for onboarding or annual refresher training, this Module is seamlessly deployable on any LMS and can be tailored to your company’s exact needs.

Duration: 30 Mins

Grade: Core Library

Description

- Identify Process Flow Diagram Symbols: Understand the symbols used to represent key process equipment such as reactors, filters, pumps, and heat exchangers to improve your ability to read and interpret PFDs.

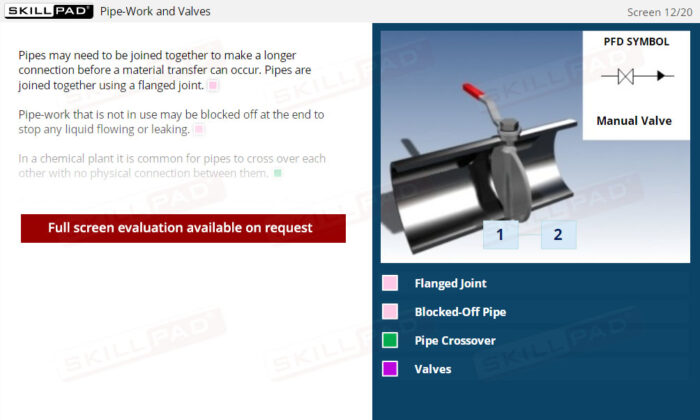

- Identify Gauges and Valves: Recognize different gauges (temperature, pressure, flow, etc.) and valves (manual and automatic) on PFDs, and understand their roles in process monitoring and control.

- Improve Process Monitoring Skills: Use PFDs to track and control chemical processes, supporting product consistency and compliance with safety protocols.

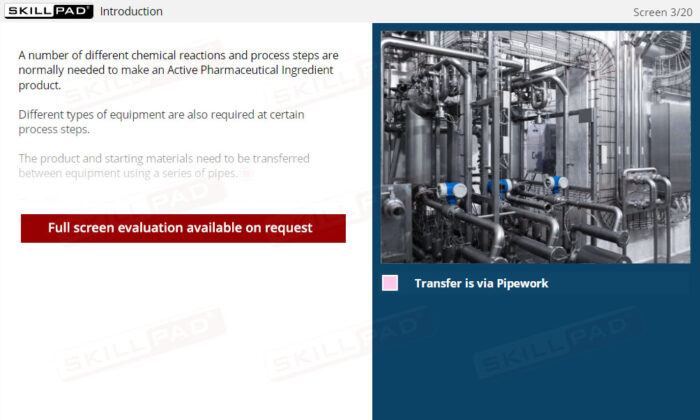

- Optimize Operational Efficiency: Understand the role of pipe-work, pumps, and heat exchangers in material transfer, and learn how to interpret PFDs to enhance operations and reduce errors.

- Understand Control Systems: Learn how control gauges and valves are integrated into processes for both automatic and manual adjustments, contributing to process optimization and safety.

Learning Objectives

- Explain the purpose of Process Flow Diagrams (PFDs).

- Identify the PFD Symbols used to represent reactors, filters, centrifuges, condensers and distillation columns.

- Identify the PFD symbols for indicating, recording and control gauges.

- Describe the PFD symbols used to show pipe-work, pumps and heat exchangers.

- Explain the difference between manual and automatic valves and how they are indicated on a PFD.

- Read and interpret basic process flow diagrams.

Keywords

- Automatic Valves

- Chemical Manufacturing Equipment

- Chemical Process

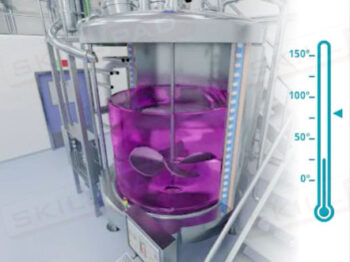

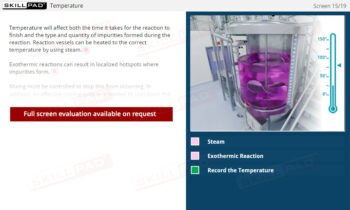

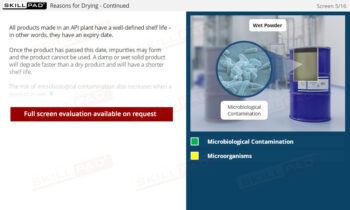

- Chemical Reactions

- Centrifuges

- Control Gauges

- Control Valves

- Distillation Columns

- Filters

- Fluid Flow Regulation

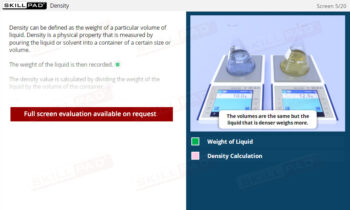

- Gauges

- Heat Exchangers

- Hazard Alarms

- Manual Valves

- PFD Symbol Interpretation

- Pipe-work

- Process Control

- Process Control Systems

- Process Flow Diagrams (PFDs)

- Process Equipment Representation

- Process Monitoring

- Process Safety

- Pumps

- Pressure Gauge

- Process Transfer

- Reactors

- Record Gauges

- Temperature Gauge

- Valve Operation

- Flow Gauge

Module Features

Animations

Voice Over

Knowledge Checks

Assessments

SCORM/AICC compatible

Full Screen