Rotary and Centrifugal Pumps

A focused exploration of rotary and centrifugal pumps, their operational principles, and their application in pharmaceutical processing. This module covers key concepts such as priming, pulsed flow, vapor bubbles, and cavitation, while introducing the various types of pumps used in the industry. Through practical examples, it delves into the workings of rotary gear pumps, centrifugal pumps, and liquid ring pumps, emphasizing their specific uses, safety precautions, and how to prevent issues such as cavitation and static electricity buildup.

Whether for onboarding or annual refresher training, this Module is seamlessly deployable on any LMS and can be tailored to your company’s exact needs.

Duration: 30 Mins

Grade: Core Library

Description

- Understand how Rotary and Centrifugal Pumps Operate: Understand the mechanics of gear pumps, centrifugal pumps, and liquid ring pumps, and how they are used in pharmaceutical processing.

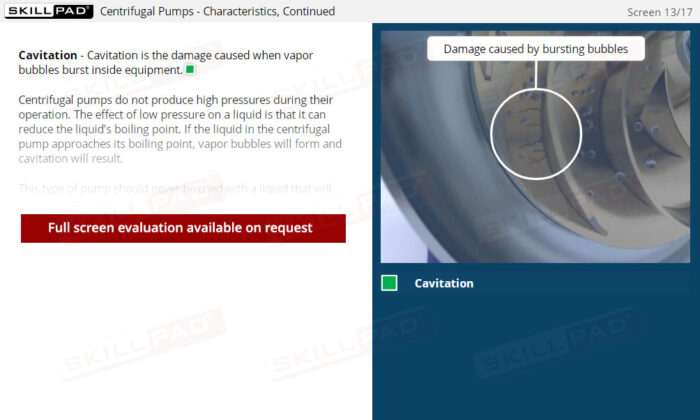

- Identify and Prevent Common Pump Issues: Recognize problems such as cavitation, pulsating flow, and vapor bubbles, and learn how to prevent these issues to maintain smooth equipment operation.

- Apply Safety Precautions When Using Pumps: Understand the safety measures required when working with pumps, including the importance of earthing and how to manage potential hazards like excessive heat, vibration, or leaks.

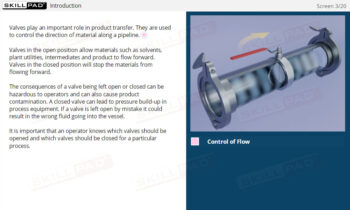

- Practical Knowledge for Pharmaceutical Processing: Learn how appropriate pumps are chosen for processing specific materials, ensuring efficiency and safety in API manufacturing processes.

Learning Objectives

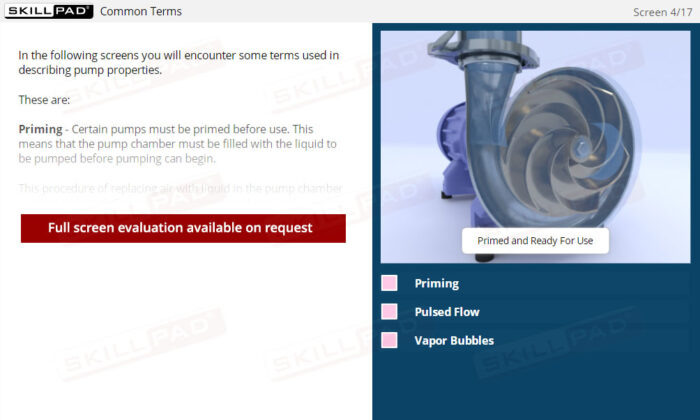

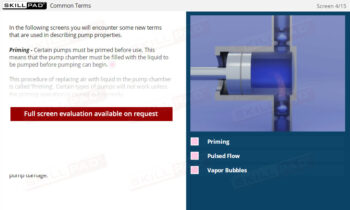

- Explain the terms ‘priming’, ‘pulsed flow’ and ‘vapor bubbles’ with respect to pump properties.

- List the three main types of pumps used in chemical and pharmaceutical processing.

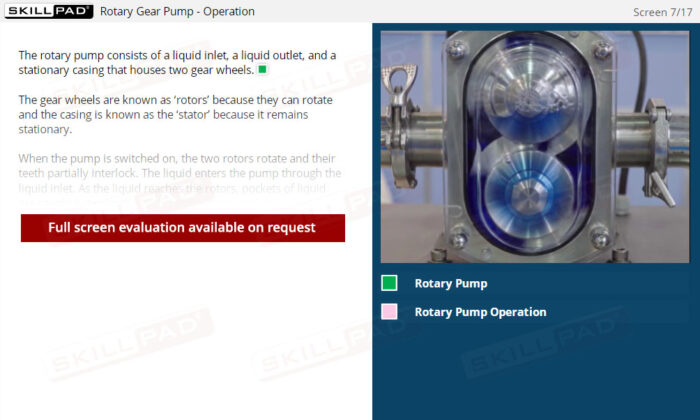

- Explain how a rotary gear pump works and describe one of its uses.

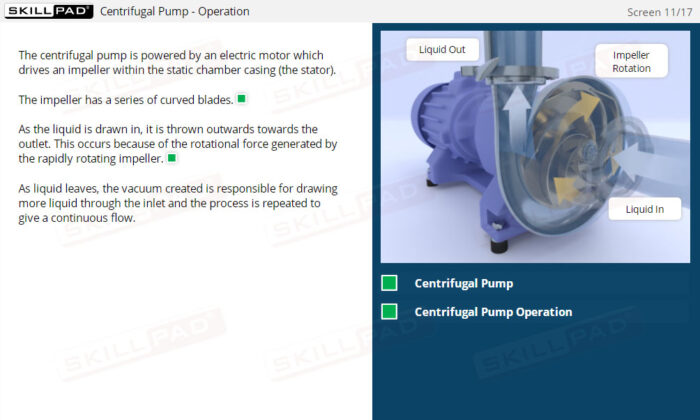

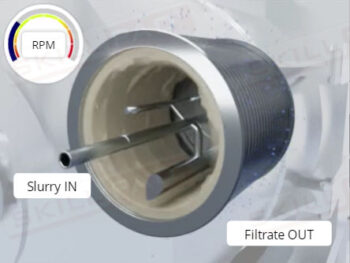

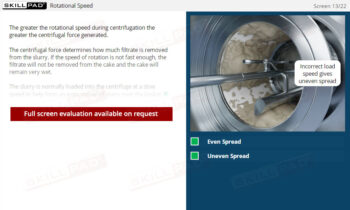

- Explain how a centrifugal pump works and describe one of its uses.

- Explain how a liquid ring pump works and describe one of its uses.

- Explain cavitation in pumps and describe how it can be recognized and avoided.

- Describe the safety precautions that must be taken when working with pumps.

Keywords

- Cavitation

- Centrifugal Pumps

- Chemical Processing

- Explosions

- Flow

- Gear Pumps

- Knowledge Checks

- Liquid Ring Pumps

- Maintenance

- Pharmaceutical Processing

- Pipelines

- Pulsed Flow

- Priming

- Pumps

- Safety Precautions

- Static Electricity

- Transferring Materials

- Vapor Bubbles

- Viscoelastic Liquids

Module Features

Animations

Voice Over

Knowledge Checks

Assessments

SCORM/AICC compatible

Full Screen