Serialization – Aggregation and Error Management

A detailed exploration of aggregation and disaggregation processes on a serialization packaging line, focusing on the parent-child relationships between serialized components such as cartons, cases, and pallets. Trainees will learn about error management strategies and the importance of minimizing errors, with a special emphasis on understanding exception events, disaggregation, and reaggregation procedures. The module also covers the critical use of the Mode 1-2-3 approach to ensure accurate manual handling and verification of serialized products.

Whether for onboarding or annual refresher training, this Module is seamlessly deployable on any LMS and can be tailored to your company’s exact needs.

Duration: 30 Mins

Grade: Premium Performance

Description

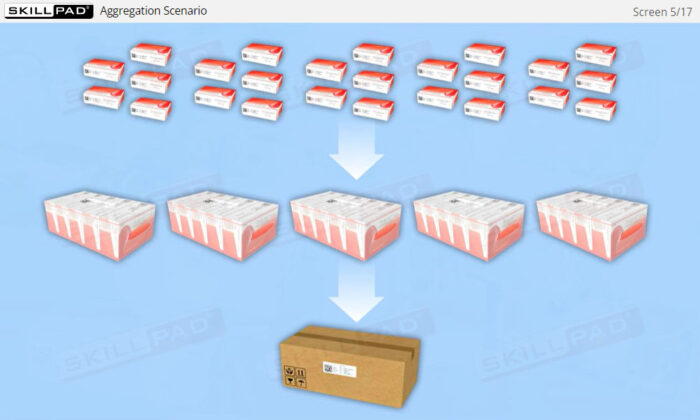

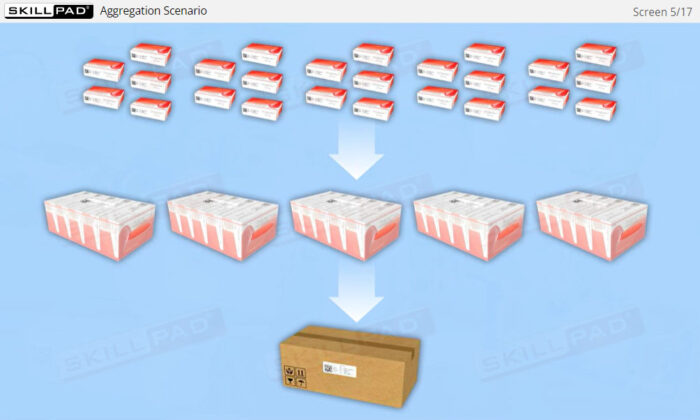

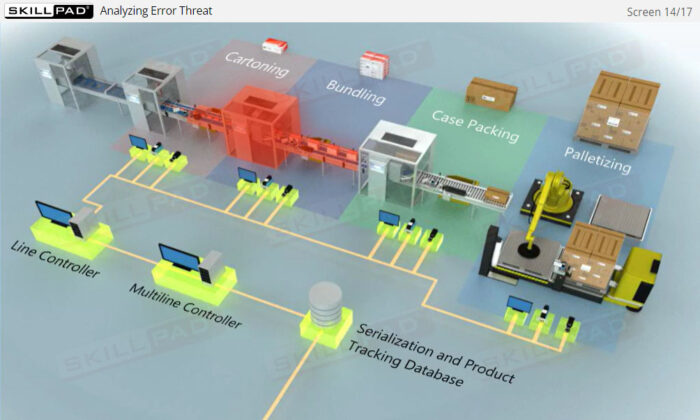

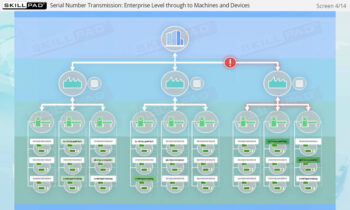

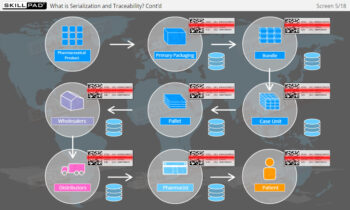

- Understanding Aggregation and Disaggregation: Gain a solid grasp of the parent-child relationship between aggregated components, including how aggregation occurs at various packaging levels (cartons, cases, pallets), and how disaggregation is managed during exception events.

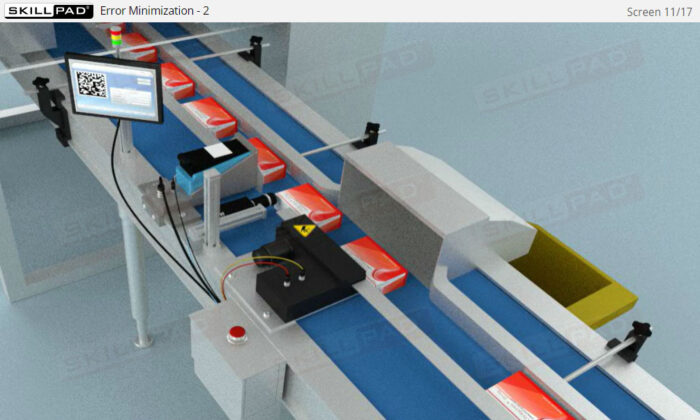

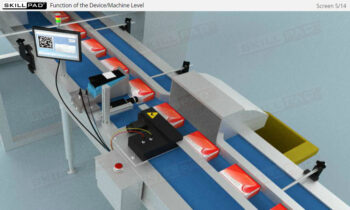

- Mastering Error Minimization: Learn to identify and manage errors that may occur during serialization processes, including printer malfunctions, scanner issues, and accidental damage. Understand the procedures to handle these errors and minimize their impact on the packaging line.

- Proficiency in the Mode 1-2-3 Approach: Develop practical skills in applying the Mode 1-2-3 procedure to serialization tasks, ensuring correct and consistent scanning, verification, and aggregation/disaggregation during manual interventions.

- Comprehensive Knowledge of Reaggregation: Understand the reaggregation process, including the handling of new items in the case and pallet, as well as the importance of ensuring that the digital and physical states of serialized items remain aligned throughout.

- Real-World Application of Normal Disaggregation Events: Learn how to handle common disaggregation events, such as uneven product quantities or damaged items, and manage these manually while ensuring serialized product integrity at all packaging levels.

Learning Objectives

- Describe the critical production line activities of aggregation, disaggregation and reaggregation.

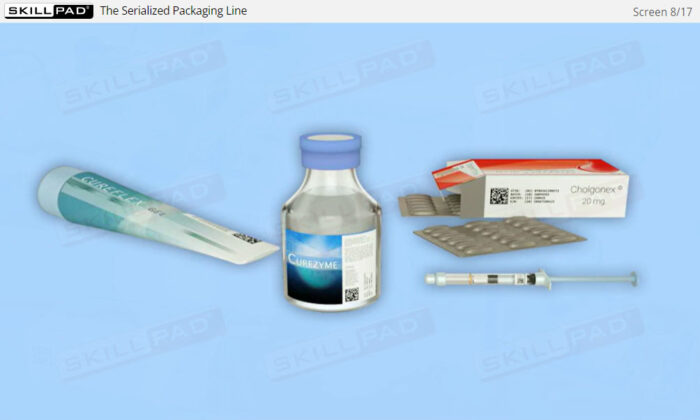

- Describe the parent-child relationship and layers of aggregation as well as errors that can occur. How items are serialized on a packaging line – items-bundles-cases-pallets.

- List the strategies for error minimization.

Keywords

- Aggregation

- Barcode

- Disaggregation

- Error Management

- Exception Events

- Mode 1-2-3 Approach

- Packaging

- Packaging Line

- Parent-Child Relationship

- Reaggregation

- Scanning

- Serialization

Module Features

Animations

Voice Over

Knowledge Checks

Assessments

SCORM/AICC compatible

Full Screen