Serialization – Exception Events, Disaggregation, and Reaggregation

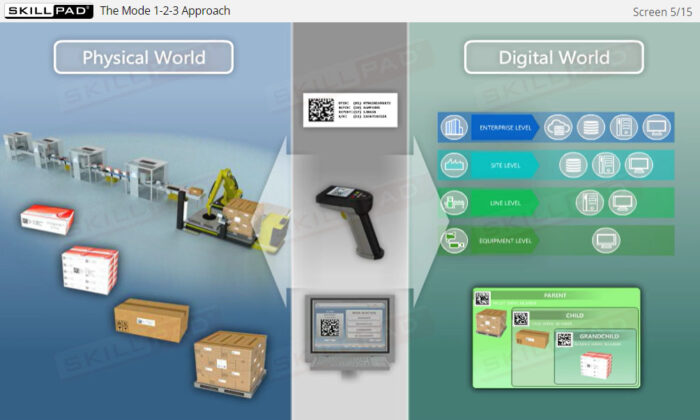

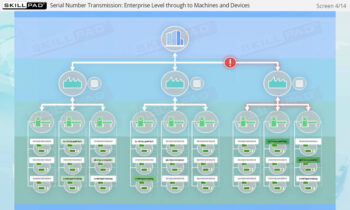

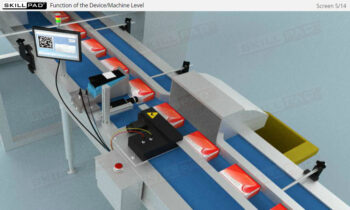

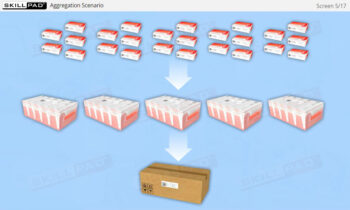

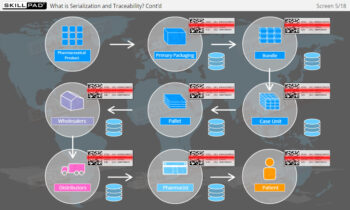

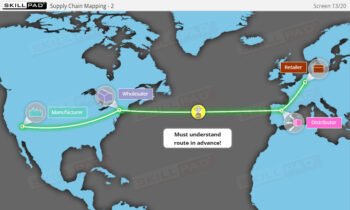

A comprehensive overview of the processes involved in exception events, disaggregation, and reaggregation within serialization systems on packaging lines. This module explores how items are serialized, the critical parent-child relationships between aggregated components (cartons, cases, and pallets), and the manual intervention required when errors occur. Operators will gain an understanding of how to manage and minimize errors through the Mode 1-2-3 approach and how to accurately handle disaggregation and reaggregation in both normal and exceptional circumstances.

Whether for onboarding or annual refresher training, this Module is seamlessly deployable on any LMS and can be tailored to your company’s exact needs.

Duration: 30 Mins

Grade: Premium Performance

Description

- Clear Understanding of Aggregation and Disaggregation: Gain a solid foundation in defining and explaining aggregation and disaggregation processes, including how serialization occurs at various packaging levels (cartons, cases, and pallets).

- Proficiency in Error Minimization and Management: Learn strategies to recognize and address error events on the packaging line, and how to calculate and minimize error threats, ensuring consistent product quality and integrity.

- Expertise in the Mode 1-2-3 Approach: Master the step-by-step procedure for managing disaggregation and reaggregation processes, with a focus on the critical role of scanning and verification to maintain serialization accuracy.

- Insight into Normal and Exceptional Disaggregation Events: Understand both standard and exceptional disaggregation scenarios, and learn how to accurately handle packaging discrepancies, such as uneven product quantities or damage, while maintaining serialization integrity.

Learning Objectives

- Describe critical production line activities of aggregation, disaggregation and reaggregation.

- Explain why disaggregation is required before the package has left the facility. This can be due to exception events such as accidental damage or normal disaggregation events such as sampling.

- Describe the ‘Mode 1-2-3’ approach for disaggregation.

Keywords

- Aggregation

- Error Management

- Exception Events

- Disaggregation

- Manual Intervention

- Mode 1-2-3 Approach

- Pallet Disaggregation

- Parent-Child Relationship

- Packaging Line

- Reaggregation

- Serial Number

- Scanning

- Warehouse

Module Features

Animations

Voice Over

Knowledge Checks

Assessments

SCORM/AICC compatible

Full Screen