Tablet Coater

An overview of the tablet coating process, explaining its purpose, equipment, and the steps involved in coating tablets. This module outlines the key parameters for controlling the process, the advantages of coating tablets, and the safety precautions necessary when working with tablet coaters. Learners will explore the function of critical equipment like the tablet coater and understand the importance of maintaining control over rotational speed, air temperature, humidity, and nozzle position to ensure consistent and high-quality tablet coatings.

Whether for onboarding or annual refresher training, this Module is seamlessly deployable on any LMS and can be tailored to your company’s exact needs.

Duration: 30 Mins

Grade: Core Library

Description

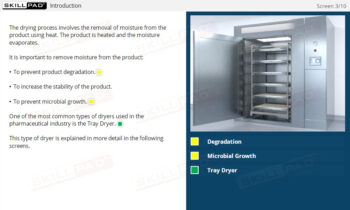

- Learn the Purpose of Tablet Coating: Understand the objectives of the tablet coating process, such as protecting ingredients, controlling drug release, and improving tablet aesthetics.

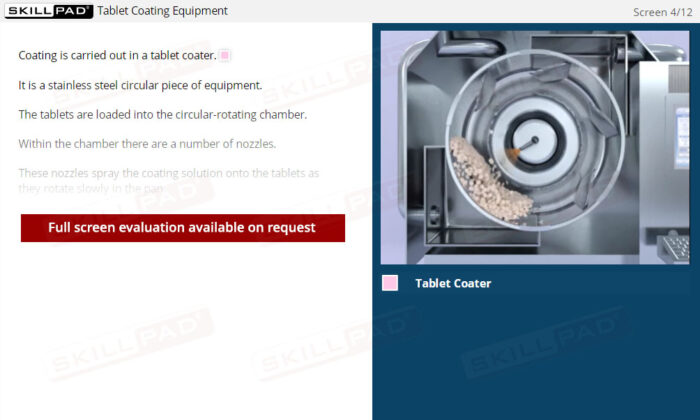

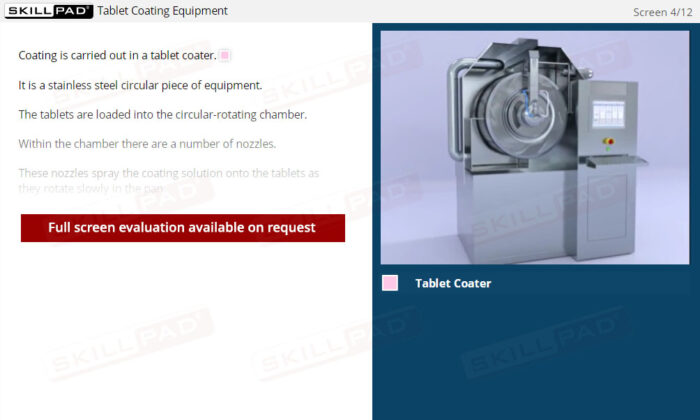

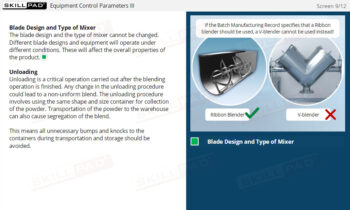

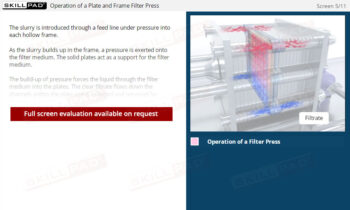

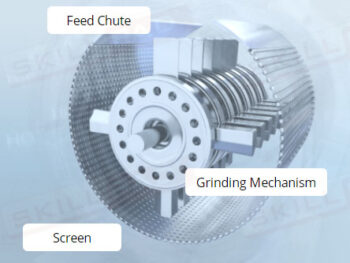

- Understand Coating Equipment: Gain foundational knowledge of the tablet coater’s basic structure, including its design, pan rotation, and nozzle configuration, to understand the equipment’s role in the process.

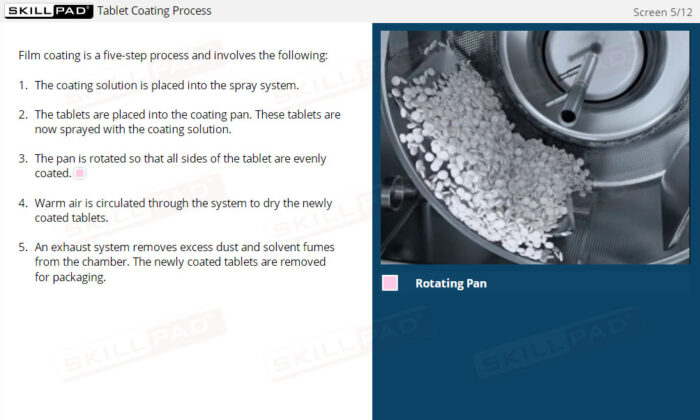

- Learn the Steps in Tablet Coating: Explore the five-step coating process, from solution preparation to drying and packaging, to maintain consistency and quality in tablet production.

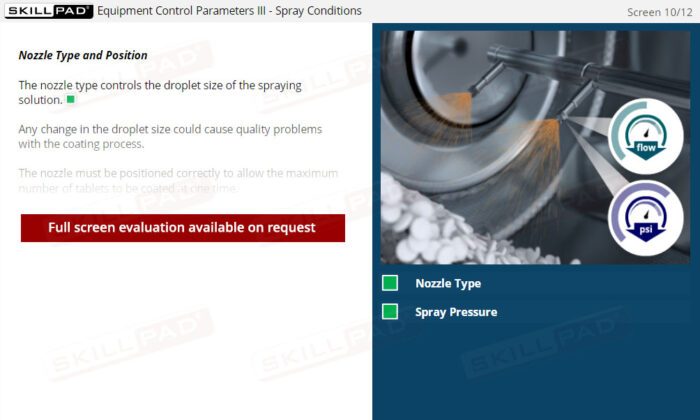

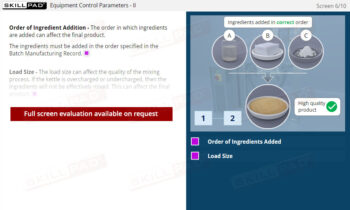

- Control Critical Process Parameters: Understand the key parameters that influence coating quality, such as pan speed, inlet air conditions, spray pressure, and nozzle positioning.

- Prioritize Safety: Learn essential safety protocols, including proper use of personal protective equipment (PPE) for handling coating solutions and precautions for working with flammable solvents and dust.

Learning Objectives

- Define the aim of a tablet-coating process.

- Describe the basic structure of a tablet coater.

- List the steps involved in a tablet-coating process.

- List the advantages of coating tablets.

- Describe the key parameters that must be controlled in a coating process.

- List the typical PPE worn when working with coaters.

- Describe the safety precautions required when operating a tablet coater.

Keywords

- Critical Parameters

- Drug Release

- Inlet Air

- Personal Protective Equipment (PPE)

- Quality Control

- Rotational Speed

- Spray Pressure

- Solvents

- Tablet Coater

- Uniform Coating

- Ventilation

Module Features

Animations

Voice Over

Knowledge Checks

Assessments

SCORM/AICC compatible

Full Screen