Tablet Press

An introduction to the essential principles of tablet compression, focusing on the critical process of tablet formation, the equipment used, operating parameters, and safety practices. This module outlines the essential powder blend properties required for successful tablet formation, the various components of a tablet press, and the key factors that must be controlled to ensure high-quality tablet production.

Whether for onboarding or annual refresher training, this Module is seamlessly deployable on any LMS and can be tailored to your company’s exact needs.

Duration: 30 Mins

Grade: Core Library

Description

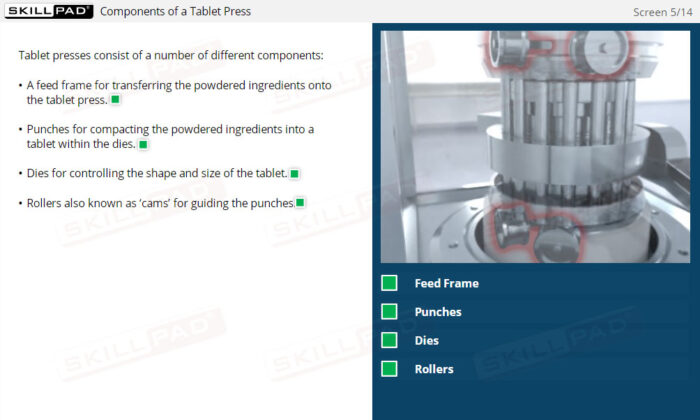

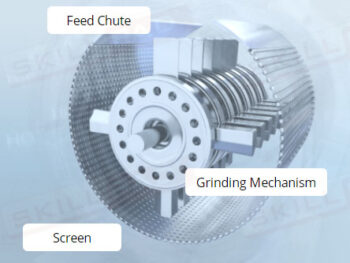

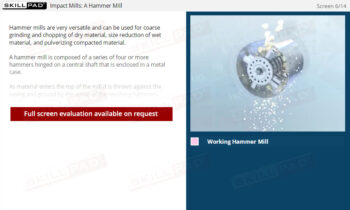

- Learn the Basics of Tablet Pressing: Understand the key components of a tablet press, such as punches, dies, and feed frames, and how they work together to produce high-quality tablets.

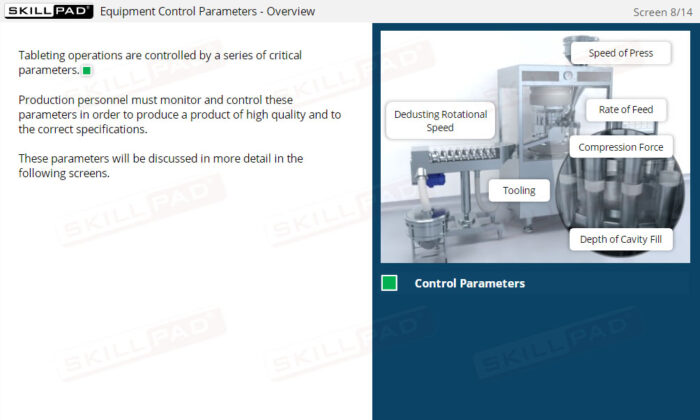

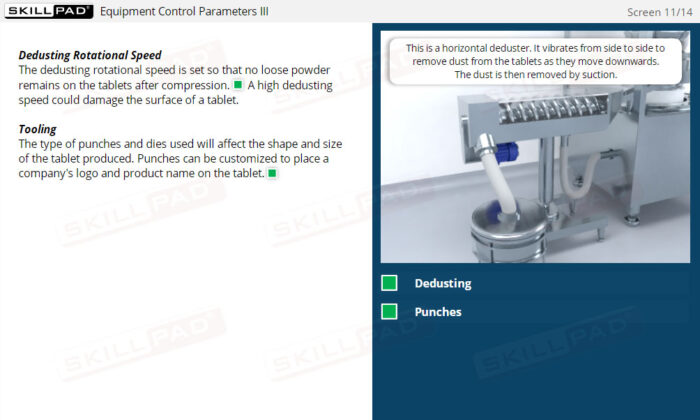

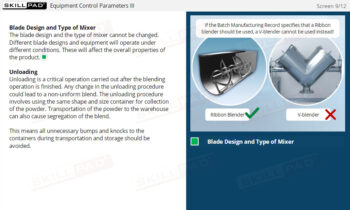

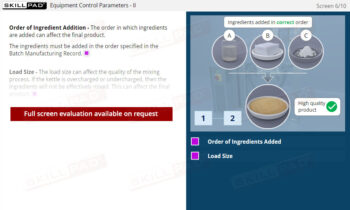

- Understand Critical Process Parameters: Learn foundational knowledge of key tableting parameters—such as compression force, feed rate, cavity fill depth, and press speed—that must be monitored to ensure tablet quality and meet production standards.

- Perform Tablet Quality Tests: Learn how to perform common tablet quality tests, including disintegration, hardness, thickness, and weight tests, to ensure tablets meet required specifications for performance and safety.

- Prioritize Safety Practices: Understand the importance of using the correct personal protective equipment (PPE) when operating tablet presses and learn how to mitigate risks related to powder inhalation and machine operation.

Learning Objectives

- Describe the essential powder blend properties necessary for successful tablet formation.

- Name the main components of a tablet press.

- Describe the basic operating principles of a tablet press.

- Name the key parameters that must be controlled in a tableting operation.

- Explain why each key tableting parameter must be controlled.

- List typical personal protective equipment that is worn when working with a tablet press.

Keywords

- Cavity Fill Depth

- Compression Force

- Dust Mask

- Hardness

- Personal Protective Equipment (PPE)

- Powder Blend

- Punches

- Rotary Tablet Press

- Safety Glasses

- Tablet Formation

- Tablet Weight

- Tooling

- Weight Test

Module Features

Animations

Voice Over

Knowledge Checks

Assessments

SCORM/AICC compatible

Full Screen