Valves

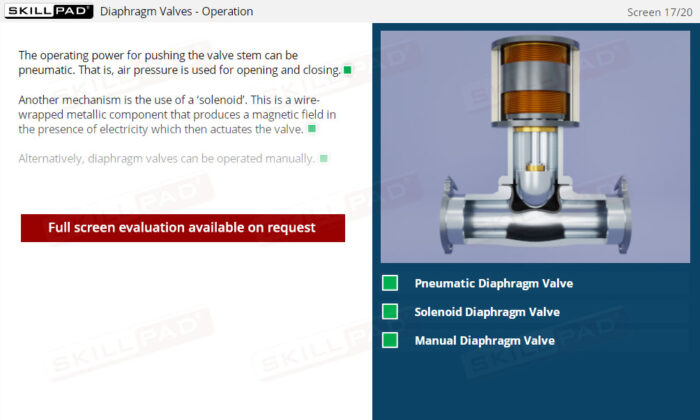

Explores the key types of valves used in pharmaceutical manufacturing, focusing on their role in product transfer and process control. It covers control valves, non-return valves, diaphragm valves, and pressure relief valves, detailing their operation, advantages, disadvantages, and common applications. Learners will gain a practical understanding of how different valves regulate material flow, prevent contamination, and maintain safety in the manufacturing process.

Whether for onboarding or annual refresher training, this Module is seamlessly deployable on any LMS and can be tailored to your company’s exact needs.

Duration: 30 Mins

Grade: Core Library

Description

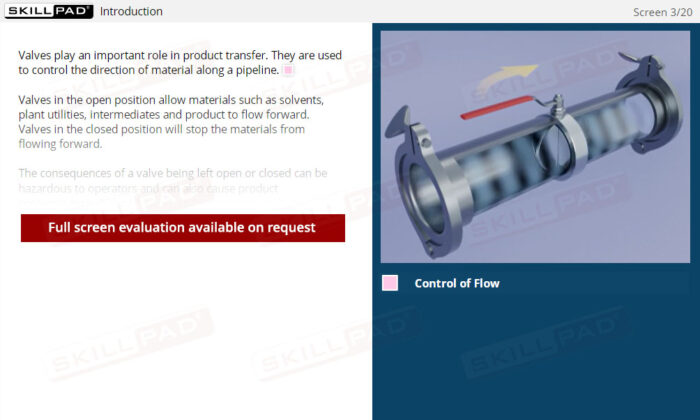

- Distinguish Valve Types and Functions: Understand the purpose and operation of various valves, including control, non-return, diaphragm, and pressure relief valves, essential for material handling in pharmaceutical manufacturing.

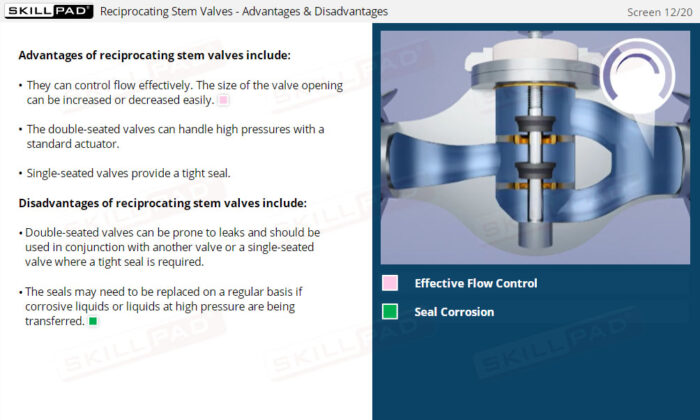

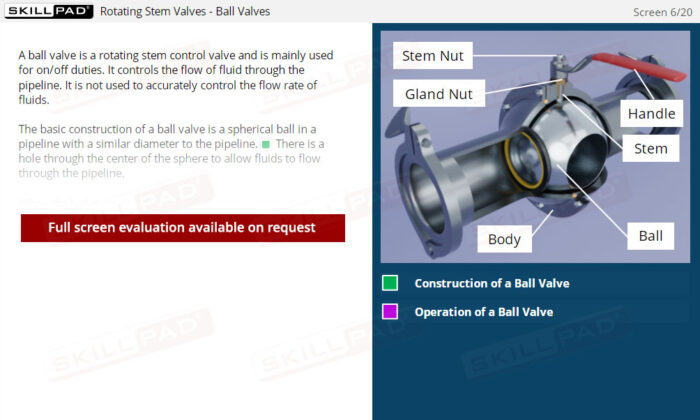

- Gain Insights into Control Valves: Explore the functions of rotating stem and reciprocating stem valves, their applications, and how they support precise flow control in pharmaceutical processes.

- Make Informed Decisions on Valve Selection: Learn the advantages and disadvantages of different valves, such as ball, butterfly, and diaphragm valves, to help select the right valve for specific product transfer tasks.

- Understand the Role of Non-Return Valves in Contamination Prevention: Learn how non-return valves control flow direction, prevent contamination, and protect product integrity.

- Build Awareness of Safety Features: Understand how pressure relief valves and bursting disks manage excessive pressure in reactors and help prevent potential hazards in manufacturing systems.