Aseptic Processing: Working with Biosafety Cabinets

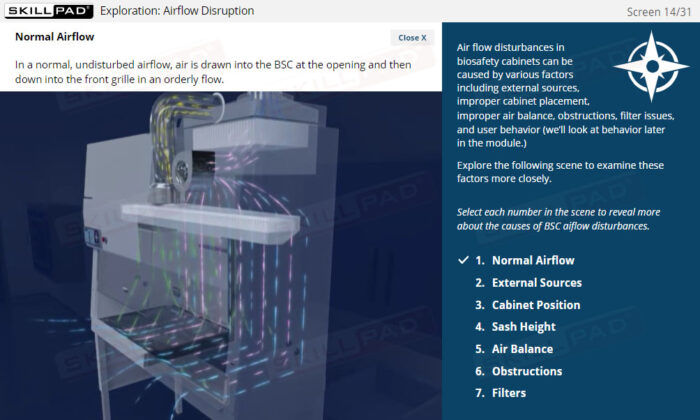

Principles of working with biosafety cabinets focusing on the role of Class II BSCs in contamination prevention. It includes airflow visualization, essential under EU GMP Annex 1 requirements, and provides the user with practical examples of the skills, best practices, and behaviors required when working with Class II BSCs.

Whether for onboarding or annual refresher training, this Module is seamlessly deployable on any LMS and can be tailored to your company’s exact needs.

Duration: 30 Mins

Grade: Premium Performance

Description

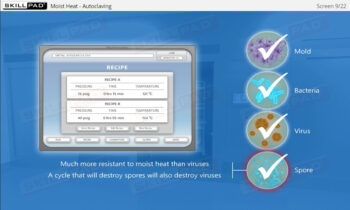

- Obtain a comprehensive understanding of the critical areas of aseptic processing by covering the essentials of aseptic processing, contamination control, and bioburden minimization.

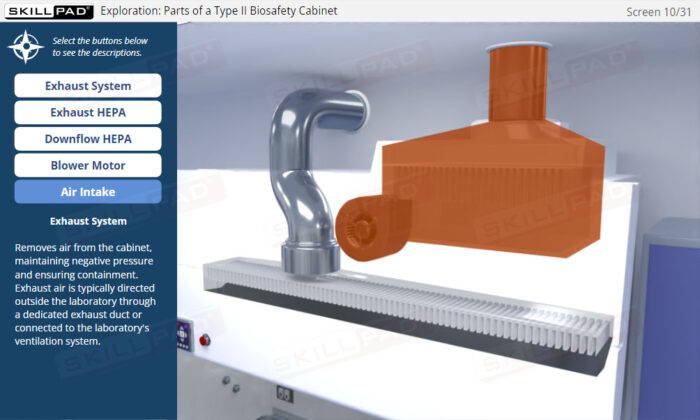

- Obtain a comprehensive understanding of the principles of working with biosafety cabinets, focusing on Class II BSCs.

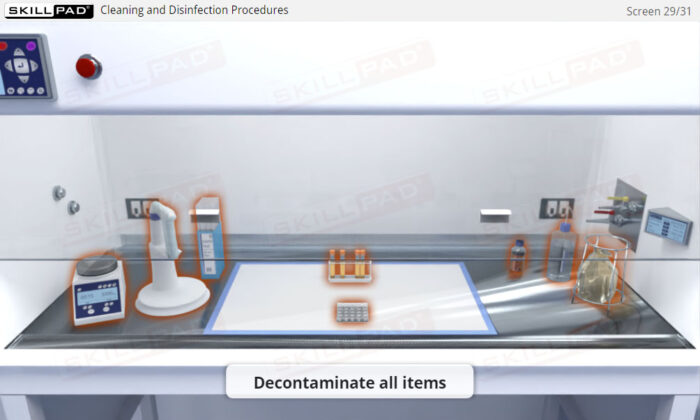

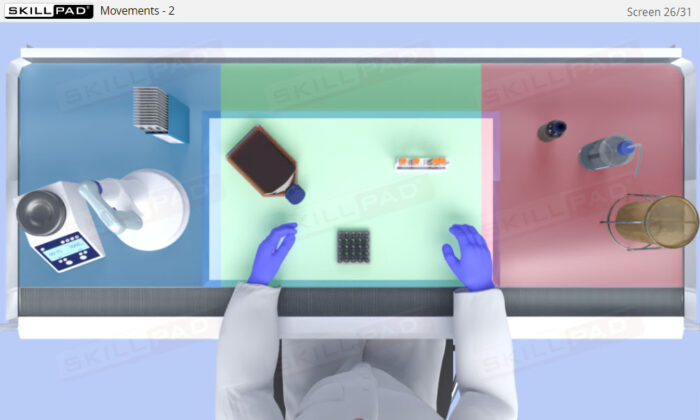

- Appreciate the criticality of preparative steps, correct movements, and post-use cleaning and decontamination procedures.

Learning Objectives

- Explain the concept of a biological safety cabinet (BSC).

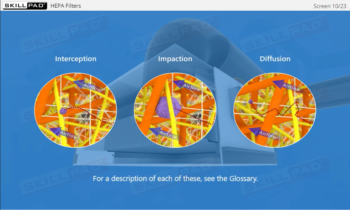

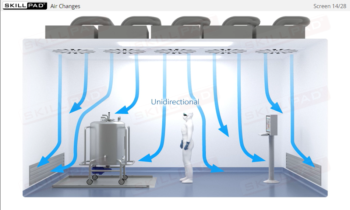

- Describe the operating principle of a BSC.

- Identify the major parts of a Class II BSC.

- Describe the preparation steps for working in a BSC.

- Describe best practices for working in a BSC.

- Demonstrate best practices for working in a BSC.

- Describe post-use cleaning and decontamination procedures for a BSC.

Keywords

- Airflow Visualization

- Aseptic Processing

- Biological Safety Cabinet (BSCs)

- Class II BSCs, Contamination Prevention

- Decontamination Procedures

- EU GMP Annex 1

- Preparation Steps

- Regulatory Compliance

- Quality Assurance

Module Features

Animations

Voice Over

Knowledge Checks

Assessments

SCORM/AICC compatible

Full Screen