Working with Reactors

The key processes involved in the operation of reactors, including proper techniques for weighing, charging, and taking samples. It covers essential reactor safety precautions, effective phase separation techniques, and detailed instructions on reactor volume measurement. Learners will also explore the importance of inerting reactors and how to safely add both solid and liquid materials.

Whether for onboarding or annual refresher training, this Module is seamlessly deployable on any LMS and can be tailored to your company’s exact needs.

Duration: 30 Mins

Grade: Core Library

Description

- Learn the Fundamentals of Reactor Operations: Understand the key processes involved in reactor operation, including charging, weighing, and sampling, to ensure both safety and product quality.

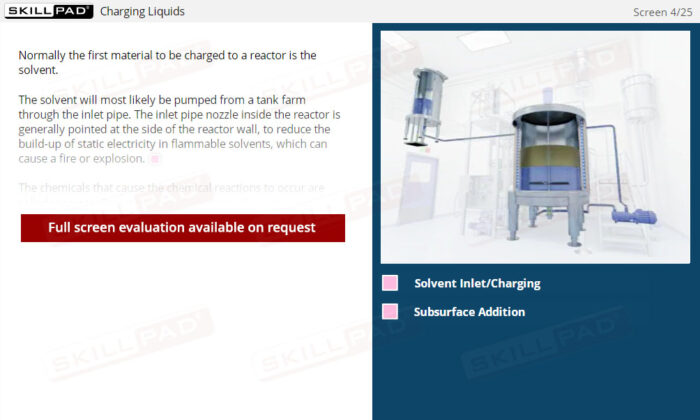

- Gain Knowledge of Reactor Charging Techniques: Learn how to safely charge solvents and solid materials into reactors, using specialized systems for handling both toxic and non-toxic substances.

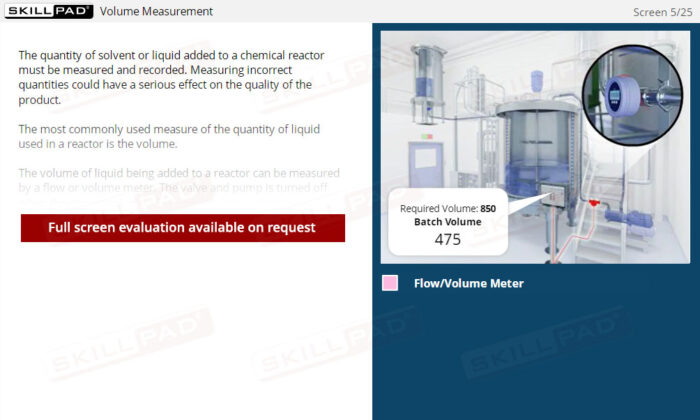

- Understand Reactor Volume and Material Measurement: Discover methods for accurately measuring and recording material quantities using tools like volume meters, dipsticks, and load cells, while minimizing contamination risks.

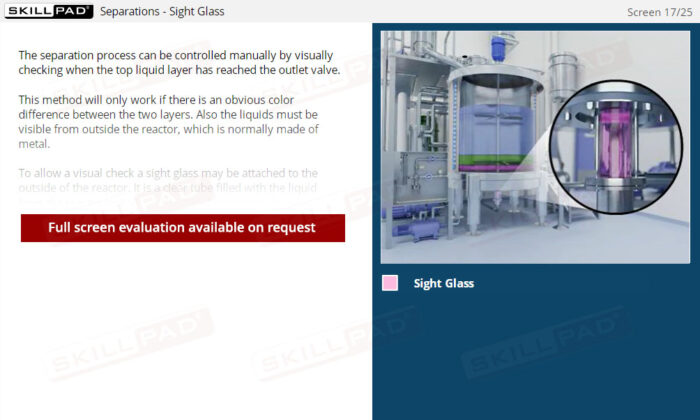

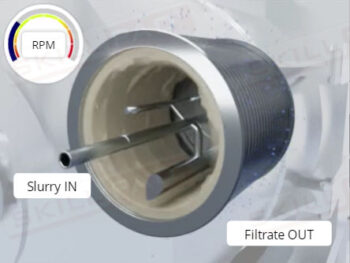

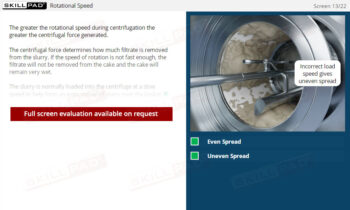

- Develop Skills in Phase Separation and Sampling: Learn effective phase separation techniques and safe sampling methods to handle mixtures while reducing exposure to hazardous substances.

- Apply Critical Reactor Safety Practices: Understand the importance of reactor safety protocols, including inerting reactors to prevent hazardous conditions, and follow safe practices throughout the chemical reaction process.

Learning Objectives

- Explain the term ‘charging a reactor’.

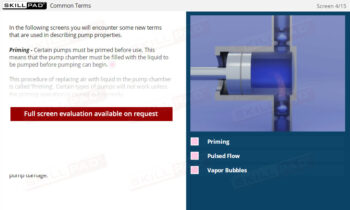

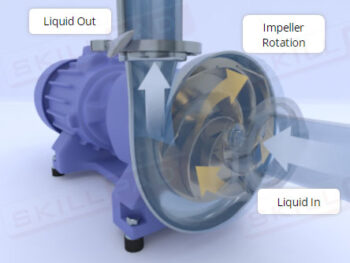

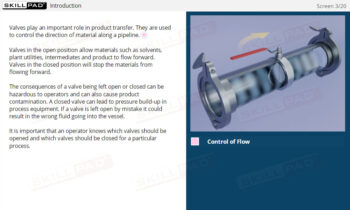

- Explain how solvents are charged into a reactor for API manufacturing.

- Describe two methods for measuring the volume of materials in a reactor.

- Explain the purpose of inerting a reactor.

- Describe how solid materials are added to a reactor.

- List and describe three ways of performing a phase separation.

- Describe two common methods for obtaining a sample from a reactor.

- Describe the general safety precautions and PPE required when working with reactors.

Keywords

- Charging

- Chemical Reaction

- Dip Can

- Dip-Pipe

- Density Probe

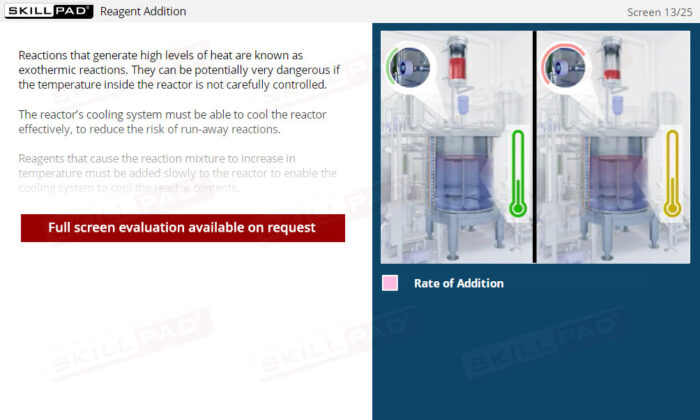

- Exothermic Reactions

- Flow Meter

- Inerting

- Interface

- Load Cells

- Nitrogen Atmosphere

- Phase Separation

- PPE

- Reactor Operation

- Reactor Sampling

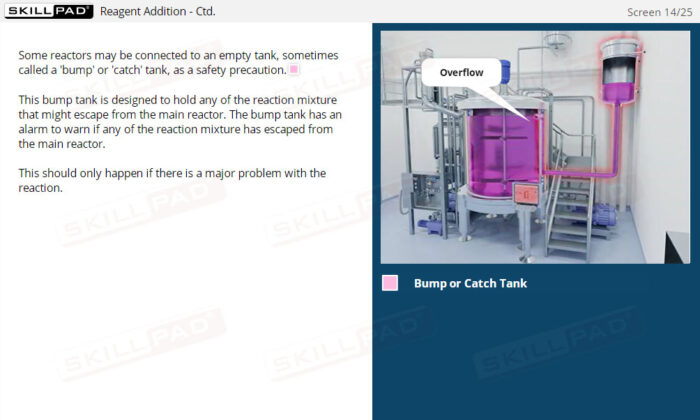

- Reagent Addition

- Sampling Loop

- Solvents

- Solid Materials

- Subsurface Addition

- Temperature Control

- Toxic Chemicals

- Volume Measurement

- Weighing

Module Features

Animations

Voice Over

Knowledge Checks

Assessments

SCORM/AICC compatible

Full Screen